HIGH PURITY WATER SYSTEMS

2011412A – AQTTB

Date Issued: 9 December 2014

High Purity water has become an integral part of our lives today. It is an essential ingredient in hundreds of applications including medical, laboratory, pharmaceutical, cosmetics, electronics manufacturing, food processing, plating, countless industrial processes and even the final rinse at the carwash.

Practically all water supplies have some dissolved impurities in the water. These impurities manifest themselves in the forms of ions such as calcium, sodium, chlorides, phosphates, sulfates, etc. The process of removing these impurities is called deionization. Deionization is the process of removing these impure ions from the water via ion exchange. Positively charged ions (cations) and negatively charged ions (anions) are exchanged for hydrogen (H+) and hydroxyl (OH) ions respectively. This all takes place in a bed of resin beads specially made to enable the ion exchange due to the resin’s greater affinity for other ions. The ion exchange takes place on the binding sites of the resin beads. Once the resin bed has reached its exchange capacity, the resin bed can be regenerated by being flushed with concentrated acid which strips away the accumulated ions leaving hydrogen or hydroxyl ions in their

place. The process is ready to begin again.

Deionizers come in four basic types: disposable cartridges, portable exchange tanks, automatic units, and continuous units. A two-bed system employs separate cation and anion resin beds. Mixed-bed deionizers use both resins in the same vessel. Mixed-bed deionizers produce the highest quality water, while two-bed deionizers have a larger capacity. Continuous deionizers, mainly used in laboratories, do not need to be regenerated.

Reverse Osmosis

Reverse Osmosis water (RO) is water purification technology that forces water through a

semipermeable filtering system under high pressure. In a reverse osmosis system the source water, which may be contaminated with salt, minerals, chemicals such as chlorine, fluoride, microorganisms or be otherwise unhealthy can be forced through a special filter of cellular acetate at high pressure. This filter only allows water molecules through and does not allow contaminates to pass through.

Water quality from DI and RO units varies with the type of resins used in the beads or the membrane technology, the quality of the feed water, flow and the efficiency of the regeneration, remaining capacity of the bed, etc. Because of these variables, it is critical to know the exact quality of the deionized water. Resistivity/conductivity is the most convenient method for testing DI water.

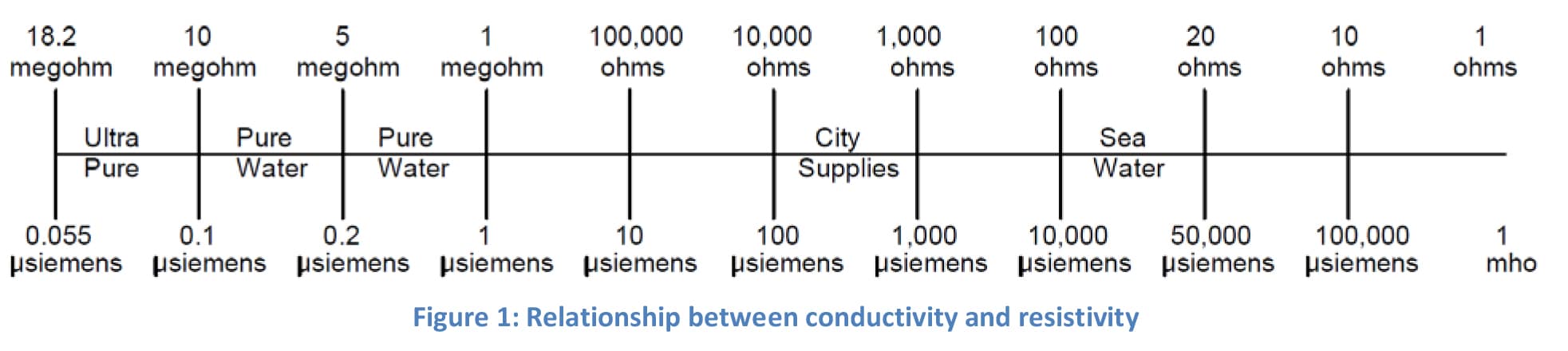

Being that all of the minerals and salts have been removed, purified water is a very poor conductor of electricity, therefore, the higher the resistivity, the more pure the water. Deionized pure water has a resistivity of 18.2 million ohm-cm (18.2 megohm), and a conductivity of 0.055 microsiemens.

An ohm is defined as the unit of resistance for every unit of voltage potential applied between two points of a conductor that will result in a current of 1.0 ampere being produced. Therefore, ultra-pure water has a resistivity of 18.2 million ohms over a gap of 1 centimeter.

Temperature also dramatically affects the conductivity of water. For this reason conductivity

measurements for high purity water are internationally referenced to 250C.

The electrical conductivity of high purity water is caused only by the presence of H+ and OH- ions, however, the lowest conductivity is achieved only in the presence of dissolved monatomic gases. Glass or plastic containers (Aquatherm Pipe) should not be used for long–term storage of high grades of pure water because these containers may release contaminants into the water. The measure of ions in the water serves as a measure of the efficiency of the filtration system used. Some more expensive filtration systems may include alarms that are conductivity based and serve to notify when filters should be replaced or resin bed should be regenerated.

The chart below shows the relationship between conductivity and resistivity of deionized water.

Useful Conversions

1/Megohm = microsiemens (micromho) 1/microsiemens (micromho) = megohm

Examples: 1 micromho (umho) = 1 microsiemen (uS)

0.5 microsiemens = 2 meghoms (2,000,000 ohms)

200 kilohm (200,000 ohms) = 0.2 megohm = 5 microsiemens

ASTM D1193-91 classifies deionized water in “Types”. For example:

Type I water = 18.2 megohm in purity

Type II water = 10.0 megohm water

Type III water = 4.0 megohm water

Type IV Water = 0.2 megohm water

High purity waters are aggressive waters and not just any pipe can be used to convey it. The water has ions missing and is searching for replacement ions. If the wrong type of pipe is used in the system, thepipe can end up being the sacrificial component to replace the missing ions in the water. The pipe will then erode and disintegrate. It is the same with fittings. Brass fittings should never be used in ultra-high purity systems. Fittings should always be stainless steel or plastic, and in some instances even stainless steel cannot be used.

Aquatherm pipe can handle the aggressive water of high purity systems and will not be degraded when used in this application

Both Aquatherm Green Pipe and Blue Pipe1 are suitable for use with deionized and reverse osmosis water systems. Generally, the Green Pipe should be used if the RO/DI process water is to be used in some way for human consumption because of the NSF potable water approval of the Green pipe. All other processes may use the Blue Pipe. Aquatherm Green Pipe and Blue Pipe have been used on a variety of DI and RO systems throughout North America. As part of the NSF 61 testing The Green Pipe is evaluated using ASTM Type II (max. 1.0 uS/cm conductivity) water for this analysis. The analysis involves exposing the pipe to this water at temperatures from 73° to 190°F, over a period of days and weeks depending on the specific leachate/analyte being tested. One additional benefit of using Aquatherm Green Pipe or Blue Pipe over other RO/DI water piping is that Aquatherm pipe is fully opaque, thus inhibiting microbiological growth.

One caveat to using Aquatherm pipe in RO/ultra-pure water systems is that at water purity of 18.0 megohms (Type I water) some components of the colorant may leach out of the pipe into the water at very low levels. This colorant leaching, although undetectable to the naked eye, may be detrimental to laboratory equipment and/or processes. It is prudent, therefore, that we verify with the owner the intended purity of the water and the end use thereof to insure that we are not selling the owner something that they do not need or want.

Revisions

- 21 October 2022 – Added Blue Pipe to acceptable piping