EQUIVALENT LENGTH OF FITTINGS

The flow rates, friction loss data and velocities for a few given flow rates are shown in the catalog. This data are the result of calculations made with the Hazen-Williams formula which is also given in the catalog. The data shows the results of the calculations showing the friction loss of the pipe in feet per hundred feet (ft./100 ft.) of pipe. Note that the pipe data in the catalog includes the losses associated with one joint (socket or butt-weld) per length of pipe, so these joints do not need to be added separately to the friction loss calculations. The velocity of the fluid flowing in the pipe per pipe size and gpm flow rate is also calculated.

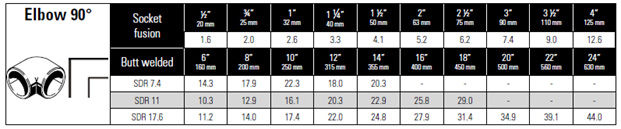

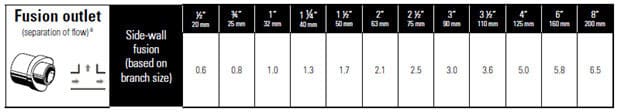

Friction loss data for the fittings is found on the pages of the catalog directly following the friction loss data for the pipe. These pages show the friction loss of the fittings in equivalent lengths of straight pipe.

For example an 8” 90 deg. elbow SDR 17.6 shows an equivalent length of 14.0 ft. This means that for every 8” 90 deg. elbow you have in your system you need to add 14.0 ft. equivalent length of pipe to the total length of pipe in your system when calculating the total friction loss.

Engineers and system designers need to know equivalent lengths of fittings and the total length of pipe in a system in order to size the system pump and ensure proper flows and pressures at fixtures and equipment.

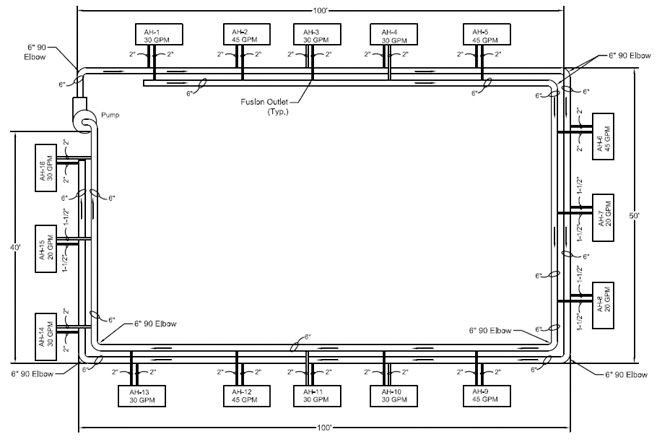

Consider the sketch below of a pumping/piping system. It can be a cooling system or a heating system or both. If we need to determine the pump size, we need to know the length of pipe involved in the system, the resulting friction head and the flow rate in gallons per minute.

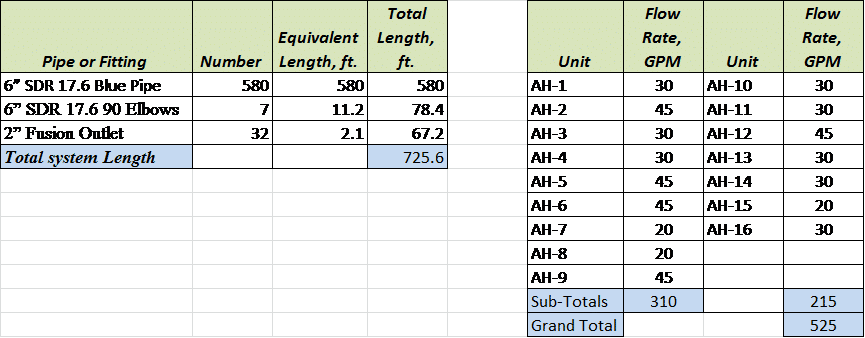

We can set up a table that looks like this:

With the total system pipe length determined (725.6 ft.) and the flow rate in gpm (525 gpm) we can size the pump. Using the Hazen-Williams formula we find that 6” pipe at 525 gpm has a friction head of 2.5 ft./100 ft. In other words for every 100 feet of pipe we will lose 2.5 ft. of head.

Another way of looking at it is friction loss in psi. In our case, we lose 1.1 psi per 100 ft. of pipe; so for every 100 feet of pipe we lose 1.1 psi of head.

With the friction head of 2.5 ft./100 ft. of pipe we can multiply this friction head by the total length of pipe, including the equivalent lengths of pipe for the fittings:

2.5 ft/100 ft. x 725.6 ft. = 18.14 ft.

Our pump will need to have a head capacity of at least 18.14 ft. The velocity in the system will be 6.9 ft. per second.