AQUATHERM BENDING AND DEFLECTING

In general Aquatherm does not recommend bending Aquatherm pipe as a means of making a change in direction or going around obstacles. However there are instances when the pipe is required to bend. When installing Aquatherm in a directional boring application or when encountering unexpected permanent obstacles in open trench applications, the pipe may need to be bent.

The pipe may be bent or bowed a maximum of 5o from straight in a 20 foot section or a bending radius of 100 x the pipe outside diameter. For an 8 inch SDR 11 pipe with an outside diameter of 200 mm or 7.87 inches x 100 = 787 inches or 66 feet bending radius.

This applies for all SDR’s and pipe diameters for the green and the blue pipe, with and without faser. The only exceptions to this are the coiled products, which have a minimum bending radius of 8 times the outside diameter.

Please note that considerable force may be required to field bend the pipe, and the pipe may spring back forcibly if the restraints slip or are inadvertently released while bending or after installation. Observe appropriate safety precautions during field bending.

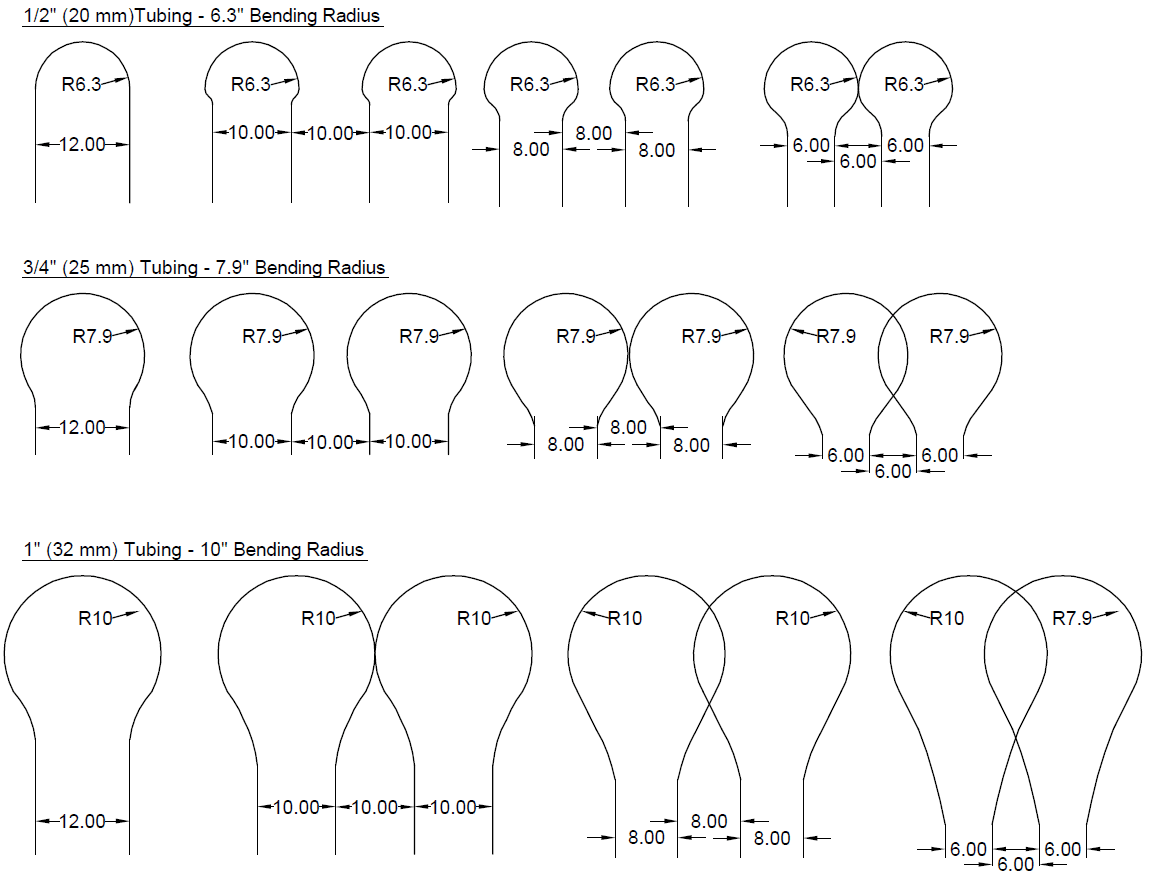

Figure 1: Bending radius in feet for comparison

When using Aquatherm coiled tubing products for radiant floor, snow melt, field/turf warming or similar applications, the bending radius should be no less than 8 times the outside diameter of the tubing being used. For example, ½” tubing (OD = 20 mm) 8 x 20 = 160 mm bending radius. 160 mm/25.4mm/in. = 6.3 inches bending radius or 12 inches on center. See illustration below for other tubing bending radii.

Always bend the tubing in the coil direction and use a bending guide to prevent kinking of the tubing.

If the application requires closer on center dimensions (10, 8, or 6 in. on center) the tubing and the loops may be overlapped to accommodate the required bending radius. Note that if the tubing is bent to a radius less than 8 times the outside diameter, the tubing may kink and create a blockage or a leak.

Figure 2: Tubing Bending Radii