Direct Burial of Aquatherm Piping

201408D – AQTTB

Date Issued: 7 August 2014

Aquatherm pipe is an excellent option for underground, direct-bury installations. The following are recommendations when using Aquatherm pipe in a direct-bury application.

Trenching

During trenching excavation ensure that the trench walls are stable under all working conditions. Provide sloped walls where appropriate and trench wall supports whenever there is a question of safety. Comply with all local, state and federal requirements for safety.

Trench Width

The width of the trench shall be dictated by the method of installation of the pipe. If the pipe is to be joined in the bottom of the trench, the width of the trench must be wide enough to accommodate men and equipment to be in the trench at the same time to perform the joining operations. If the pipe is to be joined on the surface and lowered into the trench, of course the trench width can be much narrower.

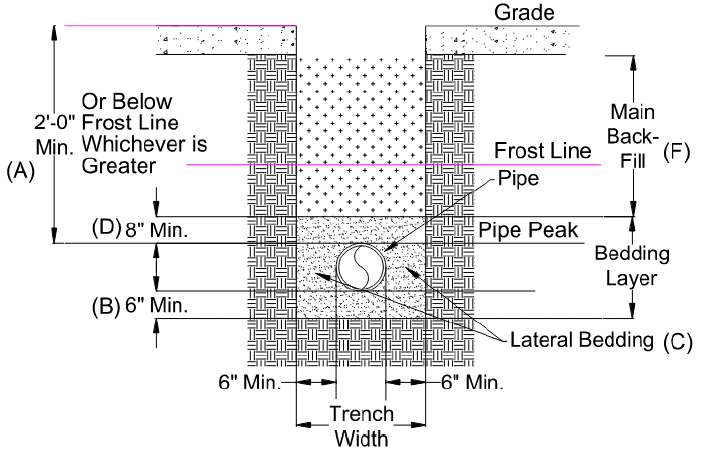

In all cases the width of the trench shall be no less than 6-in. larger on each side than the pipe being installed in the trench, i.e. if a 6 in. pipe is to be installed in the trench, allow at least 6 in. on either side of the pipe. Therefore, the minimum trench width shall be no less than 18-in. wide.

If domestic hot, heating water and chilled or domestic cold water piping are to be installed in the same trench, provide a 12” or larger barrier of 1” Blue Board between the hot and cold water piping or provide a distance of 3 times the pipe diameters between the hot and cold water piping.

The Trench Bottom2

The trench bottom shall be of native soil, relatively smooth, free of rocks and provide uniform support of the piping. The pipe shall not be supported by blocking. A minimum of 6 in. of fine granular sand shall be provided as a cushion between the pipe and the trench bottom. Sand and gravel containing a significant proportion of fine-grained material, such as silt and clay, shall be compacted by hand or, preferably, by mechanical tamper.

Pipe Embedment

The pipe embedment materials shall be stable, sufficiently granular to be readily worked under the sides of the pipe to provide satisfactory haunching, and readily compactable to achieve soil densities specified by contract documents. These qualities are available in the following materials:

- Gravels and sands classified as Soil Types GW, GP, SW, and SP, or by a dual soil classification beginning with one of these symbols, in accordance with Test Method D 2487.

- Sands and gravels classified as Soil Types GM, GC, SM, and SC in accordance with Test Method D 2487.

Initial backfill materials shall be placed in compacted layers or as specified in contract documents and local codes.

All native and other materials in the pipe embedment zone shall be free from refuse, organic material, cobbles, boulders, large rocks or stones, or frozen soils.

The particle size of material in contact with the pipe shall not exceed the following: ½ in. for pipe to 4 in., ¾ in. for pipes 6 to 8 in.; 1 in. for pipes 10 to 16 in.; and 1-½ in. for larger pipes. Each soil layer shall be sufficiently compacted to uniformly develop lateral passive soil forces during the backfill operation.

Cover

The final backfill shall be placed and spread in approximately uniform layers in such a manner as to fill the trench completely so that there will be no unfilled spaces under or about rocks or lumps of earth in the backfill. Large rocks, stones, frozen clods, and other debris greater than 3 in. (76 mm) in diameter shall be removed. When compaction is required, rolling equipment or heavy tampers shall only be used to consolidate the final backfill, provided the pipe is covered by at least 18 in. of backfill. Initial backfill materials shall be placed in compacted layers of 6 in. A minimum of 12 to 18 in. of cover is required where light traffic is expected. A minimum cover of 24 in. shall be provided for locations with heavy traffic. Refer to the technical bulletin regarding allowable loading and deflection of buried pipes for more information.

Trenches under pavements, sidewalks, or roads shall be backfilled and compacted to

the required density specified by contract documents or by the appropriate government

jurisdiction.

Aquatherm pipe may also be installed using trenchless applications by directional boring. See the Aquatherm Design and Planning Guide for allowable pulling forces. See also the technical bulletin on bending of Aquatherm pipe. For further questions or concerns, please contact Aquatherm engineering.

Thrust Restraint

Aquatherm pipe joints are heat fused which causes the pipe to become one solid piece of pipe. Thrust restraints shall not be required when installing Aquatherm pipe in a direct buried application. Anchors may be required at certain locations to ensure no movement of the pipe, such as lateral movement where the pipe enters a building foundation.

Figure 1: Trench Detail

Expansion Controls

Aquatherm pipe is strong enough to absorb the stresses and strains of expansion and contraction in and underground, direct-bury application. The pipe will not buckle nor erupt as may other piping materials, provided the installation is done in accordance with Aquatherm instructions provided here, other Technical Bulletins, and installation instructions. Therefore, expansion controls are typically not necessary when installing the pipe underground.

Pipe Locator

An electrically conductive wire should be installed with the piping to facilitate locating it with an electronic pipe locator. Other suitable material or means for accomplishing this purpose may be employed. Questions regarding the suitability of these materials/products with Aquatherm pipe should be directed to Aquatherm engineering. Effects of ground freezing shall be considered when pipe is installed at depths subject to frost penetration. Aquatherm piping is not intended to be installed in areas where it will be subjected to repeated freeze/thaw cycles.

Revisions

- 27 Jan 2023 – Revised trench detail

- 8 Jan 2024 – Revised trench bottom requirements

- June 2025 – Revised Trench Detail