Aquatherm Threaded Adapter Fitting Installation Guidelines

201912A – AQTTB

Date Issued: 12 December 2019

Aquatherm offers a wide range of threaded transitions to connect with non-fusible system components. These transitions have a machined brass or stainless-steel threaded insert molded into the PP-R base for maximum strength.

The brass transition components are lead-free (<0.25% Pb) in accordance with the Safe Drinking Water Act (SDWA).

When installing these threaded connections, there are a few important things to remember:

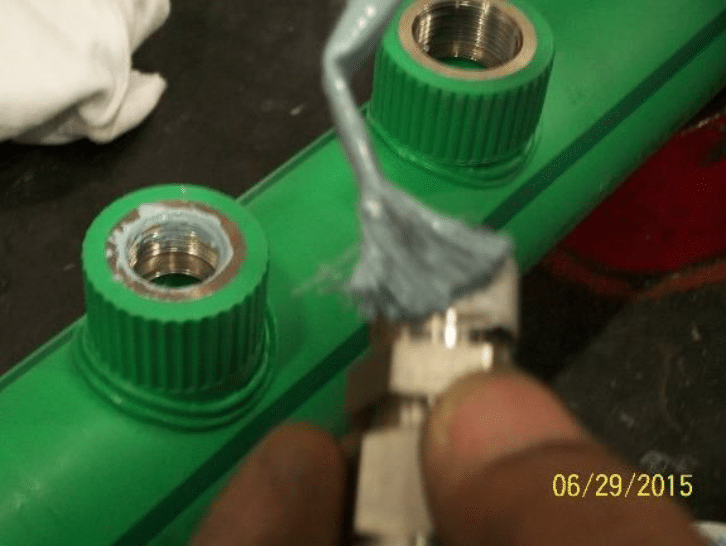

- Only continue one or two turns past hand-tight, and do not bottom out. Use tape or a thread sealant intended for use with plastic fittings, or a combination of both. DO NOT bottom out in the threaded fitting.

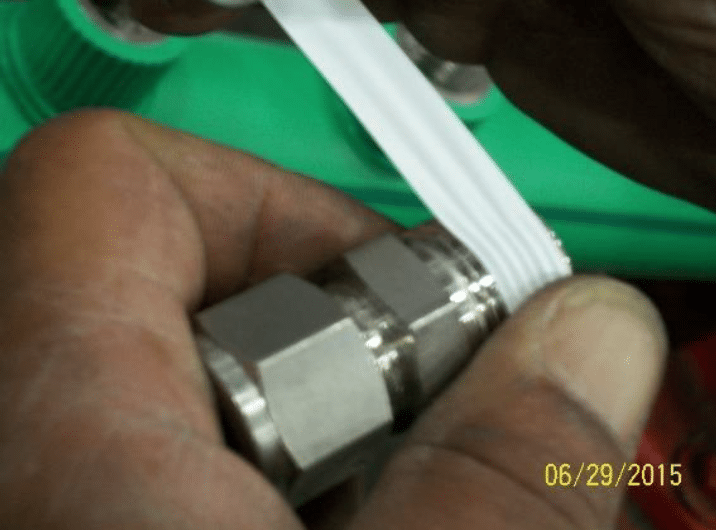

Apply 2 wraps of ½” PTFE tape (e.g. Teflon®). Holding the fitting in your left hand with the Male threads facing away from your hand, apply the 2 wraps of PTFE tape in a clockwise rotation as shown in the photos above.

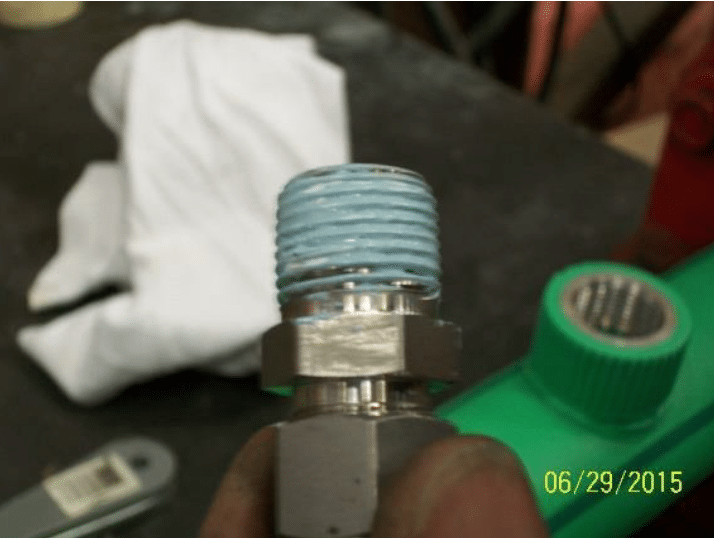

- Generally, the PTFE tape will be sufficient for helping to ensure a leak-free connection. Thread sealant may also be used in place of, or in addition to, the PTFE tape. Keep in mind that both the tape and the sealant can act as lubricants, making it easier to turn the fitting. Regardless of this, do not continue beyond 1-2 turns past hand tight. The thread sealant needs to be compatible with the brass or stainless-steel threads. However, the sealant must also be acceptable for use with Polypropylene in case of any incidental contact. Apply a thin layer of thread sealant (pipe dope) directly to the threads over the PTFE tape as shown above. The tape should not be applied over the thread sealant.

- Always apply counter torque on the metal portion of the Aquatherm fitting when tightening the connection. If the fitting has a hex head, place your wrench on it; a crescent wrench may be too wide for the hex portion, in which case a plumber’s wrench or open-end wrench may be necessary. For fittings without a hex head, use a strap or pipe wrench on the PP-R body of the fitting. Excessive torque on the brass may cause the brass to turn in the PP-R body, which will result in a leaking fitting. Never tighten the mating components to the point where the brass insert moves. Over tightening to the point where the brass insert moves will require the fitting to be removed and replaced.