OVALITY IN MACHINE ASSISTED FUSIONS

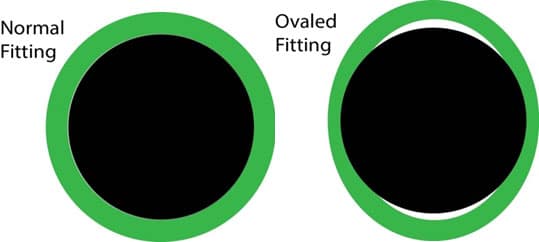

When using any fusion assistance machine, avoid clamping the fitting in a way that will cause the opening to form an oval shape. The welding heads are designed to operate under very specific tolerances, and compressing the end of the fitting can prevent proper contact, and thus proper fusion.

Some bench top machines are more prone to this issue than others, but proper technique can prevent ovaling the fitting. To determine if your machine and technique are causing ovaling, inspect the finished connection for two complete beads all the way around. If the beads are present on two sides, and absent on two sides, this may indicate that the fitting was ovaled during fusion and that the fusion weld may not be at full strength.

To prevent this issue, avoid over-tightening the clamp that holds the front of the fitting. In order to maintain proper alignment, use the backstop, or support the fitting with your hand during insertion. The jaws of the fitting clamp are intended to maintain alignment during the fusion process, and are not intended to provide the full axial support needed to hold the fitting in place. The backstop or other means should always be used to hold the fitting in position, which will also reduce the chances of overtightening the clamp that holds the fitting socket.

In some cases, there are modified clamps that reduce the compressive effect on the fitting. If the issue persists, contact the manufacturer of the tool to see what options are available.