CRAFTSMEN’S SKILL WITH AQUATHERM ELEVATES NEW RESIDENTIAL BUILDING

A skilled and experienced team delivered a long-lasting, dependable, and aesthetically pleasing piping system... that delivered delivered many other benefits.

The Challenge

Ownership sought a dependable piping system, that would deliver an affordable total installed cost.

The Solution

A skilled and experienced team delivered a long-lasting, dependable, and aesthetically pleasing piping system... that delivered many other benefits in the long run.

Residents and tenants likely are to be stampeding soon to One-Six, a new residential building in Calgary, Alberta. Calgary. Located roughly 50 miles east of the front range of the Canadian Rockies, in Canada’s third-largest municipality, this new five-story, 71,763-sq.-ft. building has joined the city’s skyline.

Featuring 103 units on four residential levels, and one level of ground-floor retail One-Six possesses a sleek and sophisticated exterior design with a dark red façade mating nicely to a large and airy glass and steel atrium.

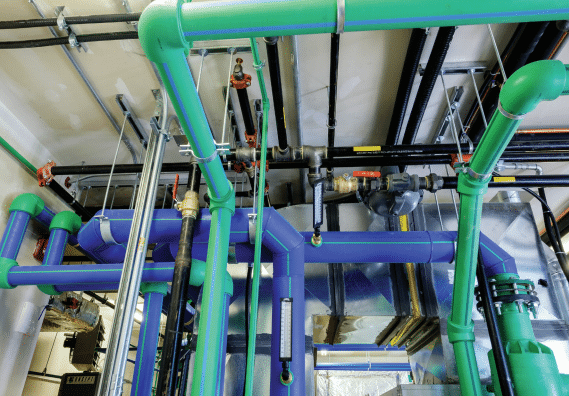

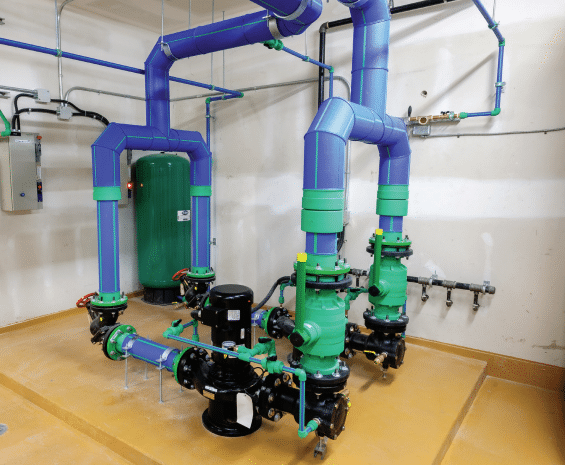

While the exterior design is attractive, below the surface is something equally sleek and sophisticated for those prone to noticing such things: the aquatherm piping system used for the building’s comfort system and domestic hot- and cold-water supply. The system is comprised of a chiller and six boilers and features extensive use of aquatherm blue® SDR 17.6 and aquatherm green® SDR 11.

Nu-Mun Contracting Ltd., Calgary, AB, recommended and ultimately installed aquatherm polypropylene random pipe (PP-R) for all the system’s mains and risers, incorporating over 750 ft of 6-in. blue SDR 17.6. The aquatherm pipe was chosen because of Nu-Mun’s extensive success and experience with it.

TRACK RECORD AND BENEFITS MAKE AQUATHERM AN “EASY CHOICE”

Nu-Mun vice president David Muncaster explained that the firm has been using aquatherm for a decade and that the piping systems offer numerous advantages compared with steel pipe, including: outstanding durability with a service life of 60-plus years; low operating and maintenance costs for the owner; and a low likelihood of being targeted by thieves at the jobsite.

In addition, aquatherm’s heat fusion process does not require a flame watch like welding does. “I hate flame watch,” Muncaster said. “It’s such a waste of manpower.”

Nu-Mun considered a few options when specifying the project’s piping systems. In the end, Muncaster said, the cost of steel fittings and the longer cure time and difficulties of gluing and priming other plastic pipe systems in cold weather ruled those options out. Additionally, Nu-Mun’s enthusiasm for and experience with aquatherm made it an easy choice for the building owner and engineer to go ahead with it.

“We recommended it and told them why we liked it, and they approved it,” Muncaster said. “At the operations level, the building’s onsite maintenance specialist had worked with aquatherm pipe before and said he was happy that we had chosen it.”

THE RIGHT TOOLS FOR THE JOB

Through the years, Nu-Mun has had hundreds of employees complete the aquatherm factory certified heat fusion training programs and currently all plumbers are certified for one or more of aquatherm’s fusion techniques, (including socket, butt and electrofusion).

Two installers spent about 10 days fabricating fittings in their 70-sq-meter shop to create custom-built rolling vertical offsets to work around the building’s structural components. The team used a Rothenberger fusion machine as well as other aquatherm-approved tools, including Ritmo socket fusion irons, a Ritmo Prisma 125 light socket fusion machine, an aquatherm-branded Delta fusion machine, and McElroy Spider 125™ fusion machines.

The wide range of tools employed reflects Nu-Mun’s investment and experience in working with PP-R piping systems. The three main tool manufacturers currently active in North America are Widos, Ritmo, and McElroy, and these innovative companies produce a large range of dozens of fusion tools, each which its strengths and specialties.

The skill of Nu-Mun’s team and their years of experience with aquatherm pipe were evident throughout the One-Six project. “We did all prefab and custom piping in house at our shop, vastly speeding up the on-site installation time,” Muncaster said.

In addition to using aquatherm blue SDR 17.6 for the supply to the open chiller, Nu-Mun vice president David Muncaster explained that the company also used it for the drain from the chiller, thanks to the inherent quality and strength of the fused joints.

ACROSS AND UP

The blue SDR 17.6 travels down the building’s fifth floor hallway, just over half the length of the building, before transitioning into a vertical riser. In an impressive feat of fabrication, the aquatherm pipe wraps 270 degrees around a stairwell and passes through a trash disposal room, then travels down the backside of the stairwell before entering a mechanical room in the parking garage. The mechanical room incorporates custom pre-built 90-degree elbows, offsets, tees, and take-offs. Other key components of the system include six Weil-McLain Evergreen 399 boilers, a Baltimore Aircoil chiller, ClimateMaster heat pumps, Thermotek makeup air units, and Grundfos pumps.

Muncaster explained that Nu-Mun has gained extensive experience with aquatherm pipe over many years, in projects that have included numerous commercial four-story walk-ups, custom homes, and 15 condominium buildings ranging in size from 10 to 160 suites.

This project illustrates just how versatile the product can be in the right hands.

“We’ve been using aquatherm pipe for more than a decade, so we know how it can help us solve very challenging situations,” Muncaster said. “I think it’s safe to say we have more experience working with aquatherm pipe than any other company in Canada.”

HALVING LABOR

Per Muncaster, the ability to custom-fabricate the aquatherm piping offsite at Nu-Mun’s shop presented a huge labor and cost savings over steel pipe. He estimated that labor costs on the One-Six project would have doubled if the company had tried to use steel instead of aquatherm piping.

There were some really tricky custom fittings we could only make in aquatherm, because we knew it was light enough that our crews could then get it in place,” Muncaster said. “The number of welds we did offsite with aquatherm were pretty extensive, and if we had been using steel the number of welds would have been mind-boggling.”

As sometimes happens in the construction world, the project’s original engineering firm left the project following what Muncaster described as unsuccessful attempts to bring the budget in line, and Allen Wasnea Engineering Ltd., Edmonton, Alberta, was called in to get the project back on track.

Colin Middleton, principal, Allen Wasnea Engineering, said his firm managed to complete the project work in a very tight timeline, thanks in large part to Nu-Mun’s experience with the aquatherm pipe and the product’s versatility.

“David Muncaster was very instrumental in helping us size the system, because being all metric means the sizing is totally different than standard pipe sizes,” Middleton said. “He helped us greatly with his knowledge of what the aquatherm pipe was capable of based on his extensive experience with it.”

MORE THAN JUST A PRETTY PIPE….

Middleton also was pleased with how much attention to detail Nu-Mun put into the project and how aesthetically pleasing the company made the piping look. “The piping is important, but so is how the contractor puts it all together,” Middleton said.

“We can design using any kind of pipe, but how the finished product looks often depends on the contractor’s attention to detail. In this case, Nu-Mun made it very neat and tidy and professional-looking. In addition to looking great, it met all of our flow requirements and worked as designed.”

The building, which was completed in September 2017, is being rented out to occupants and tenants, and Muncaster is confident that although they may never be aware of the role aquatherm and Nu-Mun Contracting played in their comfort, they will be happy living or working in the One-Six.

“This project turned out really well. I’m very happy with how it looks, the overall quality, and how it works. aquatherm has been a fantastic product with nearly zero issues in the 10 years we have used it,” he concluded.