The Data are In: ‘Hyperscale’ Data Center Selects Reliable Aquatherm Pipe

aquatherm blue plays a key role in ensuring the data in the new Novva “hyperscale” data center stays cool and secure.

The Challenge

This provider of data center space needed cooling pipe with ultra-high reliability to ensure the safety and security of its clients’ data. The “hyperscale” flagship data center is planned to ultimately include more than 1.5 million square feet of data center space

The Solution

For the peace-of-mind that makes this data center truly start-of-the-art, the cooling system for the computer servers boasts aquatherm PP-RCT piping that will provide reliable, virtually leak-free service for decades to come

Businesses that entrust their data storage to the state-of-the art Novva data center outside of Salt Lake City, UT, will benefit from a location chosen for its many data center-friendly attributes. The area offers outstanding connectivity, low power costs, and a central-western site with easy access to a major international airport. In addition, the site’s climate and 5,000-ft. altitude allow for many hours of free cooling annually.

The main entrance of the Novva data center and headquarters in Utah.

Just as important to Novva’s clients, the new data center has a low disaster risk. The area is not prone to earthquakes, floods, or adverse weather events such as hurricanes.

And finally, for the additional peace-of-mind that makes this data center truly start-of-the-art, the cooling system for the computer servers boasts aquatherm PP-RCT piping that will provide virtually leak-free service for decades to come. The aquatherm piping will never scale or corrode, and the cooling water flow will remain unchanged throughout the anticipated 50-year lifespan of the pipe. All of this data adds up to a win for Novva and its clients.

The “hyperscale” data center in Salt Lake City will be Novva’s flagship data center. The 100-acre Utah campus is planned to ultimately include more than 1.5 million square feet of data center space and will accommodate 250kW to 30 MW clients. The construction is taking place in four phases. The first phase, which includes a 300,000 sq ft data center, a 120MW substation and an 80,000 sq ft headquarters office building for Novva, was completed in December 2021.

BEATING THE HEAT

Reliable cooling systems are an essential component of modern data centers. Computer servers are notorious for generating heat—and heat is notorious for being an enemy of computer servers.

The decision to install aquatherm pipe as part of the new data center’s cooling system was driven by Steven Boyce, vice-president of infrastructure and design at Novva Data Centers. Boyce has been involved in the IT and data center space for more than 20 years, and has worked on multiple successful startups during that time.

When I first learned about aquatherm, it was a no-brainer,” Boyce said. “I had been using steel pipes in my builds, which would corrode and rust, and in turn, fill my equipment with sediment and pieces of rust. Efficiencies would be diminished, and the pipes would eventually have to be replaced. aquatherm’s total installed costs are lower, and their warranty is something that no steel vendor could match.”

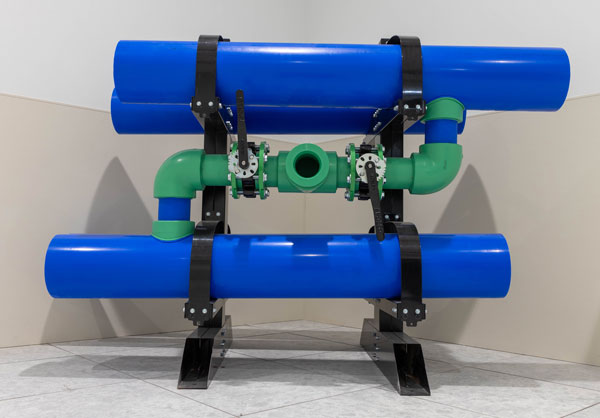

Custom spools of 10-in and 4-in. aquatherm pipe were used at the new Novva data center in Utah.

Once the decision was made to trust the cooling system’s performance to aquatherm pipe, Novva turned to the Salt Lake City branch of Harris Mechanical for the installation.

Harris had experience installing aquatherm pipe, although the Novva data center represented the company’s largest data center aquatherm installation to date. To handle the first phase of the Novva system, Harris installed a BASX custom chiller package (which included the pumps and controls), the aquatherm pipe for computer system cooling, and the comfort system piping and plumbing. The piping work for phase 1 began in mid-May 2021 and was completed in October 2021. The system was commissioned and turned over to the owner in December 2021.

FAST AND FURIOUS

Jeff Reading, operations manager, construction, Harris Mechanical, explained that the Novva data center started out as a core and shell project, with the office built first and the data hall scheduled to be built out later. However, as anyone in construction work knows, it’s always best to expect the unexpected.

“We finished the core and shell construction in May 2021, and the data hall was right on its heels as a change order to the original project. So it came at us fast and furious,” Reading said. “The original plan was to complete the entire chilled water loop, which runs underneath the floor on both sides of the building. However, it was decided to install the piping in stages as the facility is built out. So far we have installed about half of the piping that will ultimately go in there.”

The installation to date has included 4,418 ft of aquatherm blue SDR 17.6. The main system piping is 10-in., and the takeoffs are 4-in.

TRAINING PROFESSIONALS

aquatherm’s BIM and Scan-to-Fab services were key to a smooth installation of the underfloor cooling system.

To handle such a large project. Harris Mechanical sent several installers to aquatherm’s U.S. headquarters in nearby Lindon, UT, for training.

Having aquatherm-trained technicians opens up new opportunities for HVAC and plumbing companies. The company gains differentiation in the market, and enjoys the time- and labor-savings associated with installing polypropylene pipe.

aquatherm training is the most intensive, comprehensive training in the polypropylene piping industry. Attendees receive both classroom training and hands-on training with multiple fusion machines, and must pass a rigorous test using all the fusion tools correctly.

After the training, Harris completed the installation using McElroy fusion tools and a combination of socket fusion for the 4-in. pipe and butt fusion for the 10-in. pipe. The system runs at a low pressure (35 to 45 psi); the cooling system supply water runs at 55°F and returns to the chiller at about 60°F.

According to Reading, Harris Mechanical had a good experience with aquatherm piping at the Novva data center, and the ease of installation compared to steel pipe helped Harris stay ahead of the project’s tight schedule.

“It was a smooth process,” he said. “We definitely gained experience and confidence with the pipe throughout the project, and our installers became accustomed to ‘leapfrogging’ and working with more than one [fusion] machine at a time.”

BIM and SCAN-TO-FAB PAVE A SMOOTH PATH

The underfloor piping system presented one of the major installation challenges at this project. The floor is raised 5-ft., and all of the facility’s piping, wiring, HVAC ducting, and utilities run through the raised space.

aquatherm’s building information modeling (BIM) capabilities and Scan-to-Fab service helped ensure that the installation went smoothly by preventing underfloor conflicts and collisions.

“Using 3D BIM and Revit really helped with coordinating this installation,” said Autumn Turner, a fabrication drafter at aquatherm. “Not only was all the HVAC and plumbing under the floor, there were floor stands every square foot. It took a lot of coordination to avoid all those potential obstacles.”

Custom spools of 10-in and 4-in. aquatherm pipe were used at the new Novva data center in Utah.

Turner noted that careful coordination enhanced the already-fast heat-fusion installation of aquatherm pipe, and that less time and money spent on welders is a major benefit of choosing aquatherm.

“aquatherm is just easier work with than steel pipe,” she said. “It takes a lot less time to weld, and when you add in the BIM support and drafting it was easier for the installers to get situated into the floor and navigate the space.”

Turner added that aquatherm’s BIM and Revit capabilities will ensure the future installation phases of the massive project also go smoothly.

Rhett Coles, aquatherm’s fabrication drafting/scan-to-fab manager, said that aquatherm’s Scan-to-Fab service and in-house fabrication makes any piping installation easier and smoother. Spools can be custom made in any size or configuration and shipped to the jobsite ready to install. In addition, any pieces fabricated by aquatherm are covered by a comprehensive 10-year warranty.

“In the case of the Novva data center, we were in constant communication with Steven Boyce and the owner’s group,” Coles said. “We were not providing a cookie cutter system to them. They would tell us whatever they wanted or needed and we would work directly with them to help them fully accomplish their goals.”

A reliable, leak-free piping system with a long life span, and a smooth installation in any space, including challenging underfloor designs? The data are in: aquatherm is the right choice for data centers.

Novva’s dry cooler eliminates the need to use mechanical cooling in the colder months.