FLORIDA BREWERY PRODUCES COOL SUDS WITH AQUATHERM GLYCOL PIPING SYSTEM

aquatherm provided all that and more, including a 10-year multimillion dollar warranty and proven success in breweries.

The Challenge

Ownership sought the strongest, most reliable, longest lasting, and affordable pipe system it could find for its chilled water system.

The Solution

aquatherm provided all that and more, including a 10-year multimillion dollar warranty and proven success in breweries.

aquatherm PP-R piping proves best choice for crack- and leak-free system

Boston, Denver, Portland and Chicago are obvious hot spots for the craft-beer crowd, but Jacksonville, FL, probably hasn’t made an appearance on many beer aficionados’ Top 10 lists. Brewmaster Ron Gamble hopes to help change that mindset with his new venture, Veterans United Craft Brewery. A former U.S. Naval Flight Officer, Gamble aspires to infuse the same spirit, pride and dedication of his military career into a line of great-tasting craft beers as well as the Jacksonville community at large.

“It’s a new market,” Gamble said. “There is more demand than supply. The opportunity is here.” And with only about eight other breweries in the Jacksonville area, he might just be right.

HIGH CEILINGS, UTILITIES ESSENTIAL FOR INITIAL STRUCTURE

Poised to open to the public in late July 2014, Gamble expects Veterans United to brew approximately 1,500 barrels of beer in its first year and has plans to double production annually for the first few years. Currently working on an IPA, blonde ale, honey-wheat ale and espresso stout, Gamble also anticipates having several seasonal varieties available throughout the year.

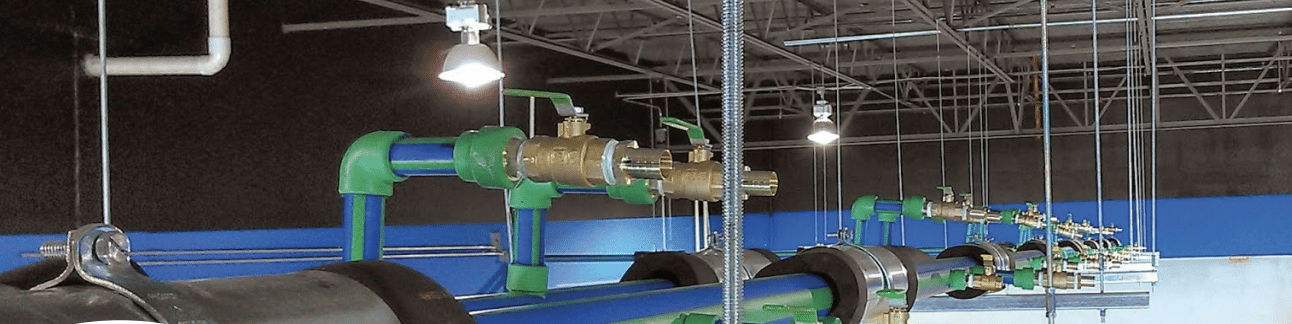

Housed in a retrofitted commercial building originally constructed in 2001, the 9,600-sq-ft space features high ceilings, which were necessary for the brewery’s large fermentation tanks. Another plus: The building was already connected to the necessary local utilities. Construction began in March 2014, and Veterans United now contains not only a substantial, open brewing area but also a taproom where customers can sip on beer by the glass, fill a growler, or purchase cans.

Having worked in breweries since 2007 and earned his Master Brewer diploma at the Siebel Institute of Technology and World Brewing Academy in Chicago, Gamble knew exactly the type of brewing system he wanted to build.

The brewing system is comprised of two kettles—the mash/lauter tun and the brew kettle/whirlpool—as well as a hot-liquor tank (HLT), which basically acts as a hot-water heater. Hot water flows from the HLT to the mash/lauter tun, in which the water is mixed with grain to create a cereal mash. The mashing process creates a sugar-rich “wort,” which then is strained in a method known as “lautering.” The wort next travels to the brew kettle/whirlpool, in which it is boiled with hops and other flavoring ingredients. At the end of the boil, the whirlpool eliminates large sediment from the final product. The wort then flows through a heat exchanger, which circulates the hot wort and cold water in opposite directions, heating the water (which returns to the HLT) and cooling the wort.

The heat exchanger’s cold water comes from a cold-liquor tank (CLT); the water cools the wort from 210˚F down to 65˚F. From the heat exchanger, wort pours into three stainless-steel jacketed fermentation tanks, each of which has a 40-barrel capacity; the tanks feature a glycol-cooling system that sits between the jacket and the inner tank and maintains a tank temperature of 68˚ to 32˚.

The wort ferments for two to three weeks, after which the resulting beer is filtered—depending on the variety—and moved to a 40-barrel-capacity bright tank in which the brew is clarified and carbonated. Finally, the signature suds are ready for packaging.

Because temperature manipulation is so integral to the taste of any beer, an important part of Gamble’s two-kettle, five-tank system is a glycol-cooling chiller and piping setup.

“I needed something that was going to last a long time,” Gamble said. “The cooling system is a critical piece of the business. If the beer is heated, it gives off byproducts that change the taste.”

To create his perfectly balanced system, Gamble wanted a contractor experienced with the specific needs of a brewery. He contacted Bernard Echt, owner of Bernie’s Boiler & Cleaners Equipment Service in Jacksonville, to build the glycol-cooling system.

GLYCOL-COOLING SYSTEM REQUIRES RELIABLE PIPING STRUCTURE

Echt had created a similar system for another local brewery and knew what Gamble needed. For the glycol-cooling system, Echt started with a 220-gal storage tank covered in black insulation containing a 35% glycol/65% water mix. A pump moves the glycol/water mix back and forth from the storage tank to an Aqua Products Company (Prosperity, SC), chiller model DCS-120C-S4B, which cools the mix to 28˚. Once the mix reaches the appropriate temperature, the chiller stops; when the temperature of the mix rises, the chiller turns on again. A second pump constantly circulates the chilled mix through a header/supply loop to the fermentation tanks.

Echt had created a similar system for another local brewery and knew what Gamble needed. For the glycol-cooling system, Echt started with a 220-gal storage tank covered in black insulation containing a 35% glycol/65% water mix. A pump moves the glycol/water mix back and forth from the storage tank to an Aqua Products Company (Prosperity, SC), chiller model DCS-120C-S4B, which cools the mix to 28˚. Once the mix reaches the appropriate temperature, the chiller stops; when the temperature of the mix rises, the chiller turns on again. A second pump constantly circulates the chilled mix through a header/supply loop to the fermentation tanks.

To connect all of the large pieces of equipment, Gamble and Echt agreed that aquatherm polypropylene-random (PP-R) piping was the right choice. Gamble knew a friend who had used aquatherm piping systems with great success at Henniker Brewing Co. in New Hampshire, and Echt had used it in his previous brewery project.

“I don’t feel comfortable using other types of plastic piping because I can’t guarantee their success,” Echt said. “[aquatherm piping systems] had a 100% success rate at the other job. We haven’t had any leaks.”

Echt didn’t even consider using another type of piping product. While the steel and copper markets can be volatile, aquatherm prices are quite stable and typically lower than traditional piping options. According to Echt, the water in Florida has high acidity levels; in his experience, copper piping installed in the area begins to leak and has to be replaced within five years. Additionally, the brewery’s glycol/water mix has to be kept around 28˚; many plastic piping systems start to become brittle and crack at temperatures below 32˚.

“Copper prices have gone so crazy. If I had used copper or steel, I would have spent 40% to 50% more in materials,” he said. “And if I had gone with PVC or CPVC, I know I would have had problems.”

Instead, Echt chose about 328 ft of aquatherm’s blue®, SDR 11, in 1-, 1½-, 2- and 2½-in. sizes. A lightweight, environmentally friendly piping system, blue is specifically engineered for hydronic, geothermal and industrial applications; the piping is high-heat stabilized and able to withstand short exposures to temperatures beyond the intended design. Echt also was happy with the PP-R piping system’s natural insulation properties; aquatherm pipes have a low thermal conductivity that provides an inherent R-value.

“The insulating factor saved money because you don’t have to install as thick of a foam-type insulation to obtain the same R-value,” he said. “aquatherm is already energy efficient.”

25% TO 50% IN LABOR COST SAVINGS THANKS TO LIGHTWEIGHT PIPING

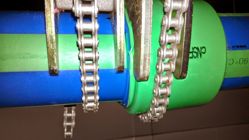

Because Echt had installed aquatherm piping systems on previous jobs, he already was trained and certified on the products’ unique heat-fusion welding process. aquatherm PP-R piping uses reliable heat  fusion to form connections; heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to ease leakage concerns.

fusion to form connections; heat fusion bonds both sides of a joint into a single, homogenous material without the use of chemicals or mechanical connections, which eliminates systematic weaknesses and fail-points in the pipe. The seamless heat-fusion connections, combined with the piping’s resistance to corrosion and abrasion, help to ease leakage concerns.

“Once aquatherm is welded in place, it’s good to go,” Gamble said. “PVC can crack and leak, but aquatherm is not prone to that.”

Echt used previously purchased socket-fusion welding system systems manufactured by McElroy and Widos, along with a rented McElroy Spider™ 125 to create his piping connections.

Proper socket fusion involves cutting the pipe, marking it for insertion depth, heating the pipe and fitting for a specified time on the heating iron, then pushing them together to cool. Once cool, the pipe and socket fitting become a single piece with no potential for leaks.

Because he was putting the system together by himself, Echt was pleased with the aquatherm piping system’s light weight. Gamble had asked Echt to run the piping system over the fermentation tanks, so he used a lift and hangers to suspend the system approximately 18 to 19 ft off of the ground.

“If I had used copper or steel, I would have had to have two or three more people on the job,” Echt said. “I wouldn’t have been able to do it myself. [By using aquatherm,] I probably saved 25% to 50% in labor costs.”

BREWMASTER READIES FOR THE NEXT STEP

Gamble is excited to get his brewery ready for production and put the system into practice. He also was pleased with his entire aquatherm experience. “[aquatherm employees] were willing to talk to us. I was able to go to another brewery and talk to a brewer and installer prior to choosing the product,” he said. “I just like the way it all came together.”