GREEN AND BLUE (PIPE) TAKE HOLD IN THE LAND OF REDS AND WHITES

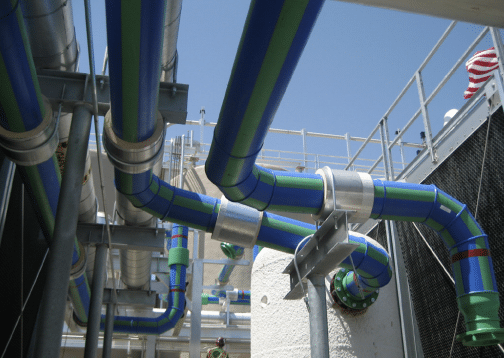

aquatherm pipe was selected as the quickly and easily installed piping solution for a variety of applications including compressed air, domestic hot/cold water and nitrogen gas.

The Challenge

Young Inglewood Vineyard and others including: Bogle Vineyards, Kelham Winery, , Gamble Estate, and Larkmead Winery, needed a highly reliable piping system that could be seamlessly integrated into their plumbing and mechanical systems.

The Solution

aquatherm pipe was selected as the quickly and easily installed piping solution for a variety of applications including compressed air, domestic hot/cold water and nitrogen gas.

aquatherm’s polypropylene-random pipe systems have gained favor as the pipe system of choice at several Napa Valley Wineries.Young Inglewood Vineyards is a two-generation, ultra-premium winegrowing estate located in Napa Valley, just southwest of St. Helena, CA. Founded by Jim and Jacky Young — after they retired from a multi-decade long career running a software company they co-founded — the winery site has been under cultivation of Vitis vinifera vineyards for more than 50 years.

WHEN WATER TRANSFER IS KEY…

The Young winery is a small boutique-style facility, yet as with any winery, the reliance on water and its transfer is essential — from domestic hot water to potable water use. And that calls for a highly reliable piping system that can be integrated into the mechanical systems without worries. To achieve optimum reliability, Young Inglewood Vineyards selected aquatherm green®, which is made from polypropylene-random (PP-R), for its water transfer needs.

According to Mark Simon, manager at Young Inglewood Vineyards, aquatherm pipe is used for all of the winery’s interior hot and cold water, nitrogen gas, and compressed air. In fact, aquatherm piping can be used for general utility services such as cooling water, reverse osmosis/deionized water, compressed air, inert gases, glycol and others.

Mike MacBriar, with Pacific Coast Plumbing (Napa, CA) and his crew handled the aquatherm installation. “aquatherm was used for every type of piping, including hot water, as well as inert gas piping. Every place where we used copper piping in the past, we are now using aquatherm,” explained MacBriar. The primary reason? “Due to the changing copper pricing these days, aquatherm, with its steady cost, is our choice,” added MacBriar.

aquatherm green is also certified for food grade applications and is ideally suited for high-temperature applications such as equipment cleaning in wineries and breweries. Operating water pressures and temperatures do not exceed 140° F or 80 psi on the domestic lines in the winery, yet aquatherm can handle 180° at 100 psi. “The pipes have less thermal loss, therefore liquids retain their temperature better,” said Simon.

A SUSTAINABLE PROCESS (AND PIPE SYSTEM)

According to Tony Costa, Costa Engineering, Napa, CA, aquatherm was introduced to the Youngs as a sustainable piping option that would perform better than conventional piping. As the designer for Pacific Coast Plumbing, Costa Engineering has been involved in several aquatherm projects, including Odette Estate (Plumpjack Winery), Young Inglewood Vineyards, and Continuum Estate (Tim Mondavi).

According to Tony Costa, Costa Engineering, Napa, CA, aquatherm was introduced to the Youngs as a sustainable piping option that would perform better than conventional piping. As the designer for Pacific Coast Plumbing, Costa Engineering has been involved in several aquatherm projects, including Odette Estate (Plumpjack Winery), Young Inglewood Vineyards, and Continuum Estate (Tim Mondavi).

Several other projects are currently in design. “These wineries that choose aquatherm are using it in applications such as domestic hot water, glycol and clean-in-place (CIP) — high temperature usage,” said Gibran Farrah, Mega Western Sales, an aquatherm independent manufacturer’s rep for California. Other Napa Valley projects using aquatherm include installations at, Kelham Winery, Gamble Estate, and Larkmead Winery, and it is also used at Bogle Vineyards south of Sacramento (see side bar).

Simply put, Costa Engineers and Pacific Coast Plumbing had no hesitation recommending and installing aquatherm. “The owner was a bit skeptical, but after looking over the product, he approved it,” said MacBriar.

In addition, MacBriar and Pacific Coast Plumbing put their faith in aquatherm for other reasons. aquatherm offers an extensive 10-year, multimillion-dollar warranty that covers any parts, labor, personal injury and incidental damages caused by material failure due to manufacturer defect. Also, “The piping is relatively lightweight compared to other metal piping, and the fact that there are no open flames from soldering used on the job-site is a plus,” added MacBriar.

PP-R WITHSTANDS LOCAL SOURCE WATER

While many other piping materials allow trace amounts of chemicals to leach from the pipe walls and into the drinking water, aquatherm’s green is hydrophobic, which prevents it from corroding or leaching. aquatherm was also chosen at the Young Winery because it is non-metallic, eliminating concerns that come with metals, including corrosion and electrolysis. “The entire Napa valley is full of silica. If you use regular water treatment, it would glaze the inside of the pipe walls,” said Costa.

While many other piping materials allow trace amounts of chemicals to leach from the pipe walls and into the drinking water, aquatherm’s green is hydrophobic, which prevents it from corroding or leaching. aquatherm was also chosen at the Young Winery because it is non-metallic, eliminating concerns that come with metals, including corrosion and electrolysis. “The entire Napa valley is full of silica. If you use regular water treatment, it would glaze the inside of the pipe walls,” said Costa.

The heat fusion connection process used to install aquatherm also drew the Costa and Pacific Coast teams to aquatherm. The pipe and fitting are placed on a 400-500° iron and then pushed together by hand or with mechanical assistance. For typical 4-in. connections, the pipe and fitting are left on the iron for only one minute and then joined together. This bonds the pipe and fitting at the molecular level without the use of chemicals or mechanical connections, and it eliminates systematic weaknesses and fail-points. The heat-fused fittings maintain the same properties as the pipe itself, so physical stresses will not compromise their integrity.

“The ease of installations in retrofit situations is a real advantage; you don’t have to solder overhead. And the reduced expansion and contraction is a plus compared to all other plastics,” said Costa.

PEACE OF MIND

In addition, the reliability associated with PP-R heat fusion connections gives owners peace of mind, especially in installation areas with high seismic activity such as the West Coast. With a faser-composite layer, which is a fiber glass extruded layer that provides rigidity and reduces thermal expansion, aquatherm can absorb shock and stress such as water hammer and moderate seismic activity. “One of the reasons we chose aquatherm was that, in the event of an earthquake, with fused connections rather than threaded, we would less likely have leaks,” said Simon.

In addition, the reliability associated with PP-R heat fusion connections gives owners peace of mind, especially in installation areas with high seismic activity such as the West Coast. With a faser-composite layer, which is a fiber glass extruded layer that provides rigidity and reduces thermal expansion, aquatherm can absorb shock and stress such as water hammer and moderate seismic activity. “One of the reasons we chose aquatherm was that, in the event of an earthquake, with fused connections rather than threaded, we would less likely have leaks,” said Simon.

So while tradition is constantly balanced with innovation in Wine Country, it’s worth noting that several wine makers have embraced a pipe technology that is both old and new: aquatherm pipes have been installed around the world for 40 years, but were only recently introduced to the U.S. market. According to Farrah, approximately 50,000 linear ft of aquatherm is installed at the wineries listed above, with more in the — excuse the pun — pipeline.

“There are so many reasons for failure of pipe systems at these wineries and aquatherm addresses so many of them, from it being corrosion resistant to chemically inert and others,” Farrah said. “It’s just a product that makes perfect sense for these applications and so many more.”