CHICAGO HOTEL SAVES LOTS OF GREEN ($$$) USING AQUATHERM BLUE PIPE®

aquatherm blue® saved the owner time and money during installation while building a longer lasting, corrosion-free system.

The Challenge

Finding a pipe material the for heat pump system that would save on material and labor costs while delivering a better solution.

The Solution

aquatherm blue® saved the owner time and money during installation while building a longer lasting, corrosion-free system.

When Ryan Kerrigan, Vice President,

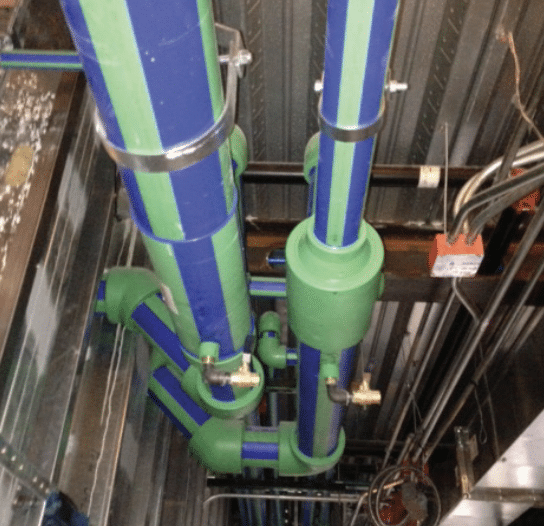

Sherman Mechanical Inc., in Cary, IL, was tasked with designing and installing the heat pump system for the new Hyatt Place Chicago-South/University Medical Center, he was presented with a different solution to the black piping that he was accustomed to using in projects of this kind. aquatherm blue® was proposed as an alternative, and since Kerrigan and his team had never used the heat-fused, polypropylene systems before, he was intrigued and wanted to learn more.

Skip Newton, with PVF Solutions, the local aquatherm representative, gave the team at Sherman Mechanical a presentation to show how aquatherm piping works. “Skip showed us how light the pipe was and how easy it was to work with,” Kerrigan said.

“I really liked the fact that the piping has thermal properties and again how light it was. One pipefitter can lift and carry a 20-foot piece of piping that is 8 inches in diameter, up on his shoulder. To do that with black pipe, you would need two pipefitters for each 10-foot section. Skip gave a great presentation and we were able to easily convince the building owner that this was an appropriate product to use.

All aquatherm pipe systems have a low thermal conductivity that provides an inherent R-value which can reduce or eliminate the need for insulation. The aquatherm 10-year warranty that covers any parts, labor, personal injury and accidental damages due to manufacturer defect also made aquatherm an easy choice for the owner.

At the time, before the aquatherm product could be installed in the building, it had to be approved by the planning committee for the city of Chicago. However, Newton and others involved with the job were able to get the product approved in the city of Chicago for mechanical building service applications.

Newton, along with Columbia Pipe, an independent company that has been providing products, service and solutions for a wide range of industries since 1935, helped get four pipefitters trained and certified to heat-fuse the aquatherm piping for the project. Heat fusion is essential to the success of polypropylene-random (PP-R) piping systems. The method joins plastic pipe and fittings by heating them to a molten state and then rapidly pressing them together to form a homogeneous, or monolithic, bond.

Newton, along with Columbia Pipe, an independent company that has been providing products, service and solutions for a wide range of industries since 1935, helped get four pipefitters trained and certified to heat-fuse the aquatherm piping for the project. Heat fusion is essential to the success of polypropylene-random (PP-R) piping systems. The method joins plastic pipe and fittings by heating them to a molten state and then rapidly pressing them together to form a homogeneous, or monolithic, bond.

Two-in.-and-below connections are made using socket fusion, which involves cutting the pipe, marking it for insertion depth, heating the pipe and fitting for a specified time (typically only seconds) on the heating iron, then manually pushing them together to bond. Once cool, the pipe and fitting become a single piece with no potential for leaks.

With pipe diameters of 4-in. and larger, butt fusion is used. This method uses a fusion machine to properly join the pipe and fitting using heat and pressure. Sherman Mechanical rented two fusion machines for one that fuses 3-in. pipe and smaller, and one for 4-in, pipe and larger, from Columbia Pipe. The pipefitters were trained on that equipment as well.

The material and labor savings on this project were significant. The mechanical room where all the piping was installed was located on the 6th floor of the 7-story, 85,000-sq-ft building. “If black pipe had been used on this job, the contractor would have had to rent a crane to get the equipment up to the 6th floor,” Newton explained. “By using aquatherm piping, they were able to walk the pipe up to the mechanical room. This saved a lot of time and cost by not having to rent the crane.”

QUICK FIX THANKS TO LIGHTWEIGHT PIPE

As with any project, you can’t expect everything to run according to plan. Two days before the hotel was supposed to open, Kerrigan noticed that the engineer had submitted incorrect drawings for the piping to the heat exchanger. This caused the pipefitter to install the piping backwards because he was following the drawings.

“We had to send a crew of two pipefitters in to re-pipe the whole system in just two days and they finished in time for the hotel to open as scheduled. If we had done this in black pipe, the repair would have taken at least a week, would have significantly increased the labor and material cost, and that would have delayed the opening of the hotel,” Kerrigan said.

“The labor savings for this project were dramatic,” Kerrigan said. “We saved between 25-45% in the labor hours. We had 1,000 hours of piping on the job and saved at least 300 to 400 hours in labor. The pipefitters in Chicago make $82 per hour, so we were able to save about $25,000 in labor. We had significant cost savings by using the aquatherm product and we were able to pass that savings along to the building owner.”

“The labor savings for this project were dramatic,” Kerrigan said. “We saved between 25-45% in the labor hours. We had 1,000 hours of piping on the job and saved at least 300 to 400 hours in labor. The pipefitters in Chicago make $82 per hour, so we were able to save about $25,000 in labor. We had significant cost savings by using the aquatherm product and we were able to pass that savings along to the building owner.”

The Hyatt Place Chicago-South/University Medical Center opened as scheduled in August 2013. The 131-room hotel employs 35 staff members and can hold up to 700 guests. According to Harold Smith, Chief Engineer at the Hyatt, there haven’t been any issues with the aquatherm piping. “This is the first time I’ve seen this type of piping,” Smith explained. “The piping doesn’t require insulation and that saved the owner a lot of extra costs. That will help the hotel keep costs down for years to come.”