GREEN PLAYERS

To this end, G Group hired local general contractor, Sawchuk Developments Co. Ltd. to construct the Southwind project. Sawchuk, which has worked throughout the Okanagan Valley since 1981, built part of its solid reputation by embracing the green building movement. So when Sandhill Mechanical was contracted to design/build the mechanical and plumbing work on the second phase of construction at the Southwind at Sarsons project, Sandhill was obliged to do the job with that objective in mind.

Completed in spring 2008, the first phase of the Southwind at Sarsons took approximately 30 months to build. Phase 1 sold out and provided a solid base for Phase 2. However, one mechanical change to Phase 2 came about when Sandhill was brought onto the project: The piping for the hybrid geothermal/domestic heating/cooling system in Phase 1 had been run using CPVC piping, which Sandhill Mechanical’s president, Grant LaLonde, prefers not to use. LaLonde explains that he’s not a fan of the chemicals used in making CPVC connections or the strength of their joints.

LaLonde also adds that copper piping has not traditionally been a good option in the area due to differing water qualities. “We’ve had problems with copper. The water can have totally different characteristics depending on where it’s coming from – wells, lakes streams – and you can have different minerals in there like manganese and calcium that can deteriorate and adhere to the pipe.”

Copper prices were also at an all-time high when the job was being designed in the spring of 2008. Additionally, copper is a finite resource and the smelting process is not entirely environmentally friendly, says Gaucher.

“Since the Southwind development was designed with environmental sentitivity in mind – appeasing the customer’s personal health considerations and their concerns for leaving a minimal building footprint on the environment, an environmentally friendly piping option fit our bill upfront,” Gaucher adds.

THE 30-YEAR-OLD “NEW” ALTERNATIVE

Sandhill did have a ready alternative that’s been proven in 70-plus countries over three decades but is relatively new to North America. The firm has installed aquatherm polypropylene piping on more than a dozen projects over the last three years, including a number of domestic water and geothermal applications.

Sandhill did have a ready alternative that’s been proven in 70-plus countries over three decades but is relatively new to North America. The firm has installed aquatherm polypropylene piping on more than a dozen projects over the last three years, including a number of domestic water and geothermal applications.

LaLonde knew polypropylene was the answer for Phase 2. “We didn’t even think of any other piping options. There are no other products that would have been satisfactory for this installation,” LaLonde says. “It’s just an overall good, long-lasting product, and its quality was important on this project,” he adds. It also helped that the material is extremely corrosion resistant, so much so that it’s frequently used in acid-waste applications.

Sandhill engaged the design-build engineering firm Aerius Engineering (Westbank, BC), whose principals were also onboard with using aquatherm. Martin Paul, P.Eng LEED® AP, and Aerius’ managing partner Dean Astren, concur with LaLonde. “We really didn’t consider any other material. Even for the larger sizes, the pipe sizing could be reduced from traditional material by virtue of the higher velocities allowed in the aquatherm,” Paul says. The polypropylene’s flow rates allowed for a 5″ installation where 6″ copper would’ve been required.

“The contractor wanted to use it and had proven that they were competent and fully familiar with the material, so we had no reason to oppose its installation,” Paul adds. When Sandhill and Aerius explained to the key players at the G Group that the polypropylene piping was a better product than what was installed in Phase 1, it was approved.

GREEN, HIGH-END CONDOMINIUM DEVELOPMENT IN KELOWNA, BC, BENEFITS FROM PIPING ALTERNATIVE

THE CREWS FUSE

aquatherm’s heat fusion process bonds both sides of a joint into a single, homogenous material, without the use of flames, chemicals, or mechanical connections. Simply putting a piece of pipe and a fitting on opposite ends of an aquatherm welding device for the specified amount of time (about 10 seconds for the 4″ pipe), and then joining them together creates an incredibly strong connection.

aquatherm’s heat fusion process bonds both sides of a joint into a single, homogenous material, without the use of flames, chemicals, or mechanical connections. Simply putting a piece of pipe and a fitting on opposite ends of an aquatherm welding device for the specified amount of time (about 10 seconds for the 4″ pipe), and then joining them together creates an incredibly strong connection.

Since Sandhill was adept in heat fusing smaller pipe diameters with the company’s basic welding tool, the only learning curve involved was incorporating heat fusion butt welding of the 6″ and 8″ pipe into their repertoire. aquatherm conducted a half-day training, and after renting the additional fusion equipment from the local EMCO office, the Sandhill crew was off and running.

“We just kind of worked through using the equipment, it was really just a matter of sequencing and how you do your joints,” LaLonde recalls. While making the fusion connections, especially in the larger sizes, took about the same time as it might have for CPVC, Sandhill did save considerable time because the systems were available for full pressure testing much quicker than solvent welding techniques.

THE LONG AND SHORT OF IT

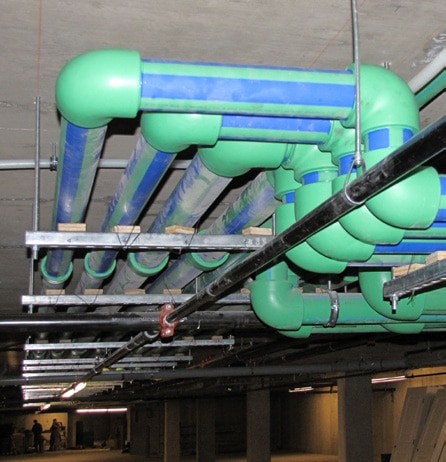

The aquatherm piping ties together all of Phase 2’s potable and HVAC systems, from the water supply provided by the Phase 1 central plant to heat exchangers, three 500-gallon water tanks, and geo-exchange heat pumps. Sandhill installed almost a mile of aquatherm green® in Phase 2, with about 1000 feet of the 3-½” (110 mm); 3″ (90 mm); and 2-½” (75 mm) pipes and plenty of other sizes including 1-½” (50 mm) and 8″ (200 mm).

The aquatherm piping ties together all of Phase 2’s potable and HVAC systems, from the water supply provided by the Phase 1 central plant to heat exchangers, three 500-gallon water tanks, and geo-exchange heat pumps. Sandhill installed almost a mile of aquatherm green® in Phase 2, with about 1000 feet of the 3-½” (110 mm); 3″ (90 mm); and 2-½” (75 mm) pipes and plenty of other sizes including 1-½” (50 mm) and 8″ (200 mm).

This has been Sandhill Mechanical’s largest polypropylene project to date. “But we really haven’t had any major challenges,” says LaLonde. “Using the big machine to do the butt fusion was new to us, but the socket fusion is straightforward. And we’ve had 100 percent support from aquatherm and EMCO.”

Aerius’ Martin Paul was also completely satisfied with the polypropylene. “The pipe is easily handled onsite and has proven to be easier to install,” he said. “The quality of the material is very good and consistent, which makes installation much quicker.”

The project, which has already been successfully tested using aquatherm’s testing standards, is scheduled for full operation and occupancy the fall of 2009. So it’s safe to say that while Southwind’s residents may not think much about the green running through their complex, the green players involved in building it are quite satisfied with it and they’ll be using it again soon.