LARGE DOSE OF PP-R PIPE PRESCRIBED AT PRESTIGIOUS HARVARD MEDICAL SCHOOL

On two separate jobs aquatherm delivered excellent results, inspiring HMS to use PP-R on several other projects, including replacement of a leaking buried chilled water line.

The Challenge

The copper supply lines feeding fan coil units were leaking at the joints and corroding, and a corrosion-resistant temporary/permanent chiller line was needed to facilitate a repair in the mechanical room.

The Solution

On two separate jobs aquatherm delivered excellent results, inspiring HMS to use PP-R on several other projects, including replacement of a leaking buried chilled water line.

Harvard Medical School, the graduate medical school of Harvard University located in the Longwood Medical Area of Boston, is one of the most prestigious medical schools in the country, and the world, for that matter. Harvard Medical School has been synonymous with excellence in education, research, and clinical care for generations.

For faculty, staff, and students alike, one key attribute that shouldn’t be taken for granted is their comfort. Studies have shown a correlation of increased performance and optimum working conditions, resulting from ideal lighting conditions, indoor air quality, and indoor temperatures.

With a mix of old and new facilities, the Harvard Medical School (HMS) facility management staff recently faced some daunting mechanical systems upgrades. In the search for cutting-edge solutions, they discovered a perfect fit. Installations at the Gordon Hall administration building and New Research Building (NRB) have given the institution the much-needed piping solution the facility engineers sought.

INSIDE GORDON HALL

The five-story, 72,877-sq-ft Gordon Hall administration building was built in 1905 and was one of the original HMS buildings. The storied structure, which has undergone multiple renovations from 1927 to present, is the main administration building which houses the medical school dean, associate deans and department heads.

The five-story, 72,877-sq-ft Gordon Hall administration building was built in 1905 and was one of the original HMS buildings. The storied structure, which has undergone multiple renovations from 1927 to present, is the main administration building which houses the medical school dean, associate deans and department heads.

HMS facilities engineer, Rob Behrent – who learned a great deal about plumbing and piping while serving as a Machinist Mate on a nuclear submarine in the Navy – was searching for a better pipe solution for Gordon Hall and the other 20-some buildings he oversees.

In early 2013, Behrent and his team were working on the plans for a retrofit involving the replacement of split DX A/C units with six Trane UniTrane® fan coil units (fcus) at Gordon Hall. “Gordon Hall was a problem because there was a lot of external corrosion on the pipes and you don’t want leaks. If it leaks, it leaks on the dean of the medical school,” said Behrent. “Some copper piping installations also exhibited similar problems with joint leaks. In addition, during colder outside temperatures, people leave windows open and the copper freezes and leaks.”

“READ ALL ABOUT IT!”

Behrent first learned of aquatherm polypropylene-random (PP-R) pipe systems when his supervisor saw a trade magazine article about them, and he thought that PP-R might be an ideal fit for the project. “We were initially going to use CPVC, but after much consideration, the cold-resistant characteristics and seismic capabilities of aquatherm piping were driving factors in the decision. CPVC can get brittle and offers very little seismic capability compared to aquatherm,” said Behrent.

Behrent first learned of aquatherm polypropylene-random (PP-R) pipe systems when his supervisor saw a trade magazine article about them, and he thought that PP-R might be an ideal fit for the project. “We were initially going to use CPVC, but after much consideration, the cold-resistant characteristics and seismic capabilities of aquatherm piping were driving factors in the decision. CPVC can get brittle and offers very little seismic capability compared to aquatherm,” said Behrent.

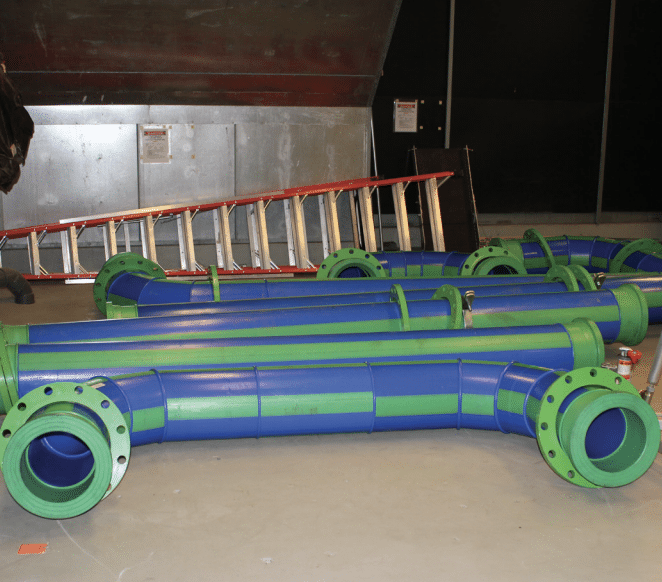

He contacted local aquatherm manufacturer’s representative, NextGen Energy Solutions, to learn more about the piping system. The Boston-based firm specializes in plumbing, heating, and cooling solutions within the residential, commercial, institutional, and industrial markets throughout New England and upstate New York. NextGen’s Chip Curtis provided Behrent with ample information about the product. Additionally, the aquatherm distributor on the job Metropolitan Pipe & Supply Company (Cambridge, MA), offered excellent support and assisted with fabrication of risers at their facility.

Behrent also worked with Engineered Solutions Inc. (ESI) out of Natick, MA, for additional engineering. General contractor JK Blackstone subcontracted the piping work to Pinnacle Piping and Service Corp., (Weymouth, MA).

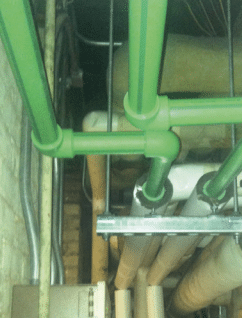

After a half-day training conducted by NextGen and renting the proper fusion welding irons, the team used approximately 200 ft of ½-in. to 2-in. aquatherm green® to run from the mechanical room to the new fcus on the second floor and provide heating and cooling to the office spaces. The installation proceeded remarkably smoothly considering it was the first aquatherm installation for HMS and Pinnacle.

“We wanted to replace ALL existing pipe, for the reasons I mentioned earlier, at some point, and this job also doubled as a proof of concept and technology,” Behrent added.

All properly installed and tested aquatherm pipe systems carry a 10-year warranty. This warranty covers the pipes, the fittings, and any incidental damage caused by material failure from manufacturer defect. The policy even provides coverage for personal injury and for financial loss. The warranty aspect of aquatherm piping was alluring, “…but the corrosion resistance was really the key driver. Anything else was icing on the cake,” said Behrent.

“In Gordon Hall, we had so many leaks that we want to completely repipe the system. Due to leaks, a repipe of the entire building’s HVAC system is planned and in the budgeting process,” said Behrent.

INSIDE NRB

Situated in the heart of Harvard’s campus, the 825,000-sq-ft New Research Building (NRB) – yet to be named – is a stone’s throw from many of HMS’s renowned affiliated hospitals and research institutions. Built in 2003, the NRB, which houses the Departments of Genetics and Microbiology and Immunobiology, is a breathtaking glass building that houses 800 researchers in state-of-the-art labs, and convenes the world’s foremost scientists working to solve the biggest medical challenges of our time. Home to the Joseph B. Martin Conference Center, the NRB hosts 470 events annually and more than 2,000 visitors daily. Everything from interrogating the genome, to unlocking the mysteries of the immune system, takes place in the NRB. The 12-story building is considered a wet lab research facility making it part of Harvard Medical School’s 2.8 million sq ft of wet lab research space.

Situated in the heart of Harvard’s campus, the 825,000-sq-ft New Research Building (NRB) – yet to be named – is a stone’s throw from many of HMS’s renowned affiliated hospitals and research institutions. Built in 2003, the NRB, which houses the Departments of Genetics and Microbiology and Immunobiology, is a breathtaking glass building that houses 800 researchers in state-of-the-art labs, and convenes the world’s foremost scientists working to solve the biggest medical challenges of our time. Home to the Joseph B. Martin Conference Center, the NRB hosts 470 events annually and more than 2,000 visitors daily. Everything from interrogating the genome, to unlocking the mysteries of the immune system, takes place in the NRB. The 12-story building is considered a wet lab research facility making it part of Harvard Medical School’s 2.8 million sq ft of wet lab research space.

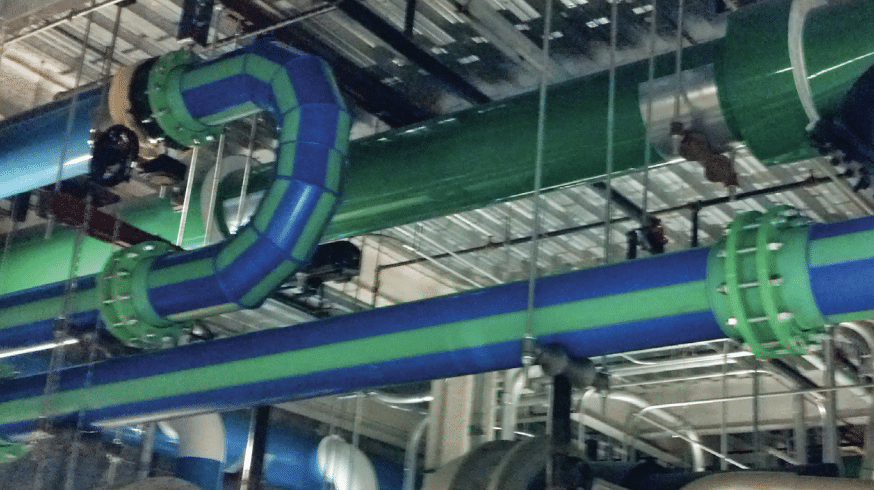

The building has 5,500 tons of cooling with 12-in. lines supplying chilled water. Problems for Behrent arose when a 24-in steel chiller condensate water line began leaking in the mechanical room. The leaks occurred in a straight section of the pipe and necessitated a replacement from the flange up to the 90-degree elbows. Replacing that section of pipe meant that Behrent and his team needed to drain the entire 24-in. line that runs to the cooling towers on the roof. It also necessitated a temporary cooling solution during the pipe repair.

Again, the team turned to aquatherm, this time using 12-in. aquatherm blue® to connect to the 12-in. chiller line which would serve a dual purpose: it would provide cooling via trailer-supplied Trane Air Cooled Chillers (ACCs) during the repair, and afterwards, would serve as a permanent installation for emergency tie-ins should HMS ever need to bring temporary ACCs in again.

DRY AND EMPTY PP-R = NO PROBLEM

The aquatherm 12-in. temporary/permanent risers were run 50 feet from the basement up through a ventilation chase to the temporary chillers located in the parking lot above the chiller vault. Since this project required the 12-in. line remain in place completely empty and dry for an extended period of time, Behrent didn’t want to use a steel pipe due to potential corrosion during this idle period.

Stainless steel wasn’t an option because of the cost, plus steel would have corroded. The external corrosion also would have been a concern because the pipe is in the air intake plenum for the chiller vault and the exhaust chase for the fans in the parking garage, which is exposed to weather.

Finally, if steel were used, the line would have needed to be charged with nitrogen to prevent rusting. “It was worth a little bit of extra cost to go with aquatherm so as to not have to go to extreme measures like charging the piping with nitrogen,” explained Behrent.

EXTRA LINE PROVIDES REDUNDANCY

With the aquatherm risers, HMS now has the ability to bring chilled water down the pipes so they can shut down the building chillers and do major maintenance or emergency repairs in the future. The chiller condensate pipe repair is ready to be performed by Interstate Mechanical Services now that auxiliary chill water lines are in place and tied into the building.

With these two important projects completed, Behrent said he and his primary plumbing engineering firm, ESI, plan to use aquatherm on several other jobs at HMS. The next one, which involves replacing a leaking buried chilled water line by using aquatherm to thread through the existing line without disrupting a parking lot, was scheduled to take place in December 2013.

It all started with an engineer who learned firsthand about the hazards of leaking pipe while hundreds of feet underwater in treacherous territory. Now he embraces a pipe technology new to North America, but proven around the world for 40 years. And one of the most respected medical institutions in the world is benefiting from that discovery.