MICHIGAN BREWERY HITS BULLS-EYE WITH ASSIST FROM PP-R PIPING SYSTEMS

aquatherm provided a leak- and maintenance-free system that has run smoothly for four-plus years - and it’s the brewery’s preferred pipe system going forward.

The Challenge

Ownership sought the most environmentally friendly piping system for the geothermal heating and cooling system serving the beer cave.

The Solution

aquatherm provided a leak- and maintenance-free system that has run smoothly for four-plus years - and it’s the brewery’s preferred pipe system going forward.

Ypsilanti brewing operation’s green focus led to aquatherm polypropylene-random playing a key role in keeping the beer flowing – and unfrozen.

Ypsilanti brewing operation’s green focus led to aquatherm polypropylene-random playing a key role in keeping the beer flowing – and unfrozen.

If there were a beer dartboard for the state of Michigan, Arbor Brewing Company would be sitting toward the center of the board. Consider: Microbreweries are growing at an amazing rate. According to CraftBrewingBusiness.com, craft beer production was up 18% annually in mid-2014. And Michigan, which is known as “The Great Beer State,” is home to 150 craft breweries.

Holding a cup that virtually “runneth over” with craft beer, Michiganders have their choice of some of the finest craft beers in the world, yet they have continually supported Arbor Brewing Company (ABC). The kegs were tapped at the ABC Pub and Eatery in downtown Ann Arbor, MI in July 1995, and the company has regularly expanded. Out-of-staters frequently take home a couple cases or growlers at a time, and the brewery recently expanded distribution to Northern Ohio and Connecticut.

A commitment to handcrafted beer, exceptional hospitality, local sourcing, community involvement, and environmental stewardship has been the foundation for ABC’s growth and success. The brewery was founded by husband and wife team of Matt and Rene Greff, who share a passion for beer and adventure. By their late 20s the Greffs had become disenchanted with their corporate gigs and soon after brewpubs were legalized in Michigan, they set about opening their own brewery. They raised their startup capital through a network of friends, family, and co-workers and became the first brewpub to open in Ann Arbor and the fifth to open in Michigan’s fledgling microbrewery movement.

Having survived some rocky early years, by 2001 ABC maxed out capacity on its seven-barrel system and expanded to an adjacent building with the addition of a small banquet space, an additional 30 barrels of fermentation and serving-tank capacity.

GROWING AND GREENING

The Greffs wanted to create another brewery to produce and bottle their award-winning beers and as long-time Ypsilanti residents, wanted to help spearhead the economic renaissance in their hometown. Thus, they selected an abandoned warehouse tucked into a residential neighborhood a few blocks off the beaten path.

The Microbrewery Brew Pub and Beergarden quickly became a regional destination and a favorite local hangout and by 2010 the brewery was bursting at the seams. So the Greffs embarked on an ambitious $1 million expansion and green brewery renovation project. In addition to the green renovations, the project doubled the amount of car parking, tripled the amount of bike parking, and added 2,200 sq ft –including new warehouse and office space, while doubling the brewing capacity, and increasing bottling speed five-fold by 2014.

According to Dan Peron, the director of brewery operations at Arbor Brewing Company Microbrewery, formerly known as Corner Brewing Ypsilanti, ownership took a very green approach to the Ypsilanti expansion.

“Doing a brewery in an environmentally friendly way is kind of something you have to be naturally inclined to want to do in terms of your product and your philosophy. You can follow suit and do what we’ve been doing for decades and centuries, or you can dig a little deeper and put forth a little bit more effort and investment to make more of an impact,” Peron said.

From the Greffs on down, the company sought to not only use the best, most natural ingredients in its brews, but also use the most environmentally friendly processing pipe, solar arrays, thermal collection system, and so forth. “It really kind of adds a little bit more to what we are all about and I think that each and every employee here in turn carries that as a badge that they’re proud of where they work and also believe in those same ideals,” Peron continued.

Mike O’Brien is known around the brewery as “Brew-Gyver.” He has earned this title (an apt reference to the 1980s show MacGyver) from his ability to creatively keep ABC’s mechanical systems running smoothly. O’Brien explained that the longevity and sustainability of the facility’s piping systems was a priority. A brewery depends heavily on all sorts of piping beyond the obvious brew process piping and thanks to a local contractor, ABC discovered a German-manufactured polypropylene piping system ideal for several of the expansion’s applications.

Peron had worked with heat-fused plastic pipe systems in the irrigation industry and was familiar with the dependability of the fusion joining method. Upon further research online, the design team felt aquatherm was the best choice for the brewery’s geothermal piping to condition the beer cave, as well as for some domestic water supply.

COME TOGETHER

“When we started to watch the contractor put the pipe in, things started to come together. It looked like the speed of the project moved along at a really good clip,” Peron recalled of the installation. At the time, the design team didn’t consider using aquatherm for the brewing chiller system; now four years later, Peron wishes that wasn’t the case. “I’m kind of bummed that we didn’t take that into consideration. Rest assured, moving forward I’ve got air process, CO2 process, and more water supply lines that we’re going to run in aquatherm.”

Peron was impressed with the idea that polypropylene is heat-fused as opposed to being connected via primers and glues or mechanical connections. “Anytime you eliminate steps you can increase a more positive outcome,” he said, adding: “The way we were able to cut and connect this pipe, it was a lot cleaner. With aquatherm, it’s just time and temperature, and there’s a much shorter curing time, there’s no risk of drips and glue to break off and get in your process lines.”

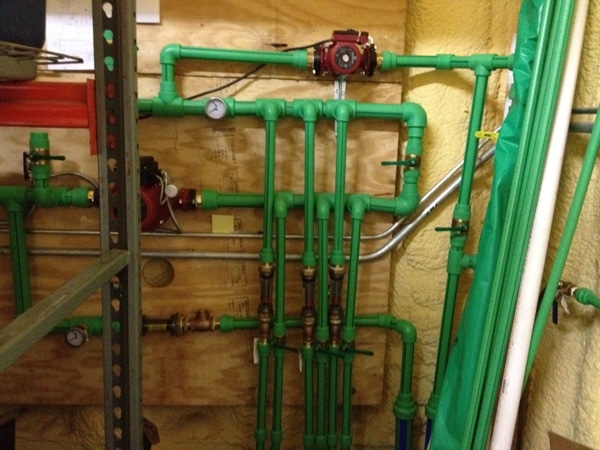

The ABC team and a local contractor installed 3,060 feet of ½-in. aquatherm blue® running from five 85-ft-deep geothermal wells to the surface, with another 3,750 ft embedded in the 6-in.-deep concrete floor of the beer cave. Additionally, 960 ft of 1-in. aquatherm green® was installed running from the wells to the building and 300 feet of 2-in. blue was used to form the perimeter of the grid.

aquatherm blue, which is designed for HVAC and industrial applications, was used in the floor and in the wells, while aquatherm Green  Pipe, which is designed for potable water applications, was used to run from the wells to the control area in the front of the beer cave.

Pipe, which is designed for potable water applications, was used to run from the wells to the control area in the front of the beer cave.

The floor grid was roughly 23 ft x 78 ft with ½-in. aquatherm blue spaced out every 6 in. to provide the beer cave’s heating and cooling, and the lines from the building to the wells were buried roughly 6 ft underground in sand/dirt.

aquatherm offers over 400 fittings and valves, and its fusion outlets offer considerable time and material savings. The heat fusion outlets played provided significant labor and material savings for the geothermal grid and the manifolds.

The fusion outlets allow branch lines to be installed when the pipe is already in place. The pipe is simply drilled into with a specially designed bit that removes the PP-R material and the fusion outlet is welded into the drilled hole. Fusion outlets connected the ½-in. pipe to the main lines.

According to O’Brien, the contractor that initially started the expansion’s plumbing installation was unable to complete it for a variety of reasons, so a second contractor assisted brewery staff in completing the project, and it all turned out quite well.

PERFORMING AS DESIGNED

The geothermal radiant system, which contains only water, is powered by a single 115v Grundfos pump. The system provides 100% of the heating and cooling for the beer cave and has been running for over four years, performing exactly as designed.

The geothermal radiant system, which contains only water, is powered by a single 115v Grundfos pump. The system provides 100% of the heating and cooling for the beer cave and has been running for over four years, performing exactly as designed.

“Keeping this space from freezing all winter without spending any money on heating is amazing because it gets really cold and there are many days when it’s zero degrees [Fahrenheit] outside. This room just never froze and it never got cold enough where the beer is in danger of being hurt a bit,” Peron explained.

He added that no maintenance has been necessary. “We’ve had zero issues with the system. It’s kind of like we set it and forget it. We make sure the water levels are set and it’s doing what it’s supposed to, but we haven’t seen any visible flaws or degradation. And it seems that according to the chemical specs sheets and what they were engineered to be used for, the possibilities for using this pipe are endless,” Peron said.

PEACE OF MIND

While ABC didn’t use aquatherm for glycol, Peron explained that the pipe’s 10-year multimillion dollar warranty makes it a no-brainer for that  application since glycol leaks can be so costly. He added that PP-R’s inherent R-value of 1 or more depending on pipe diameter was another selling point. “Condensation and dust can create mold issues. And if you’ve got mold on the premises, it’s counter-intuitive to have to clean up constantly after that. There’s less insulation needed to put onto the product, which was a big deal.”

application since glycol leaks can be so costly. He added that PP-R’s inherent R-value of 1 or more depending on pipe diameter was another selling point. “Condensation and dust can create mold issues. And if you’ve got mold on the premises, it’s counter-intuitive to have to clean up constantly after that. There’s less insulation needed to put onto the product, which was a big deal.”

The brewery produced 4,500 barrels in 2013 and was on target for 6,000 barrels in 2014 with growth remaining steady at 25-30% annually since opening in 2006. But despite the growth, ABC has experienced a 30% reduction in overall energy costs thanks to their green initiatives, providing an excellent return on investment for ABC.

And going forward, Peron said aquatherm pipe will be used in all suitable applications, including new CO2 and compressed air mains. Innovators tend to find ground-breaking products, and in this case, ABC hit a bulls-eye for their piping needs