UNIVERSITY OF FLORIDA TAPS AQUATHERM TO SOLVE STEEL CHILLED-WATER PIPING FAILURE

A mechanical contractor was able to direct-bury aquatherm polypropylene-random piping systems without insulation while eliminating any concerns of corrosion or deterioration.

The Challenge

University of Florida needed an eco-conscious solution when two of its buildings began experiencing failures in their carbon-steel chilled-water-supply pipelines.

The Solution

A mechanical contractor was able to direct-bury aquatherm polypropylene-random piping systems without insulation while eliminating any concerns of corrosion or deterioration.

INSULATION

INSULATION

The University of Florida (UF) is the oldest university in the state of Florida and—with more than 50,000 students—one of the largest universities in the U.S.

UF’s 2,000-acre campus in Gainesville, FL, consists of more than 900 buildings. The university was officially established in 1853 and part of the campus is listed as a historic district on the National Register of Historic Places, but UF is anything but mired in the past. In fact, an ongoing extensive capital improvement program has resulted in a large number of new or updated facilities that are positioned for 21st-century academics and research. Overall, the university’s current facilities have a book value of more than $1 billion.

When the university experienced unexpected leaks in its existing 1960s chilled-water pipe serving the 488,000-sq-ft Dental Science Building and 126,000-sq-ft College of Veterinary Medicine Building, it decided to replace its failing carbon-steel piping with aquatherm polypropylene-random (PP-R) pipe—not only to solve the immediate problem, but also as a new piping material for permanent replacements.

HEAT FUSION SPEEDS INSTALLATION

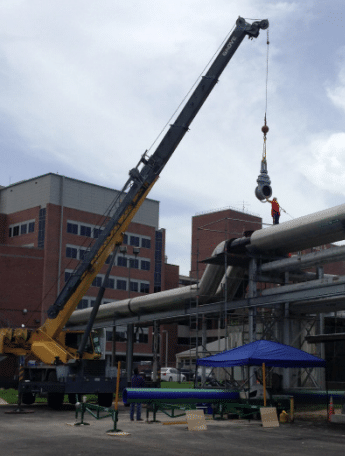

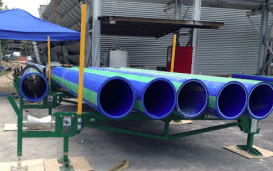

To solve the immediate crisis of the failure in the existing 24-in. underground pre-insulated carbon-steel chilled-water-supply pipeline, the team from W.W. Gay Mechanical Contractor, Jacksonville, FL, replaced about 700 ft of the system’s supply and return carbon-steel pipe with 20-in. SDR 17.6 aquatherm blue® Multi-Faser (MF).

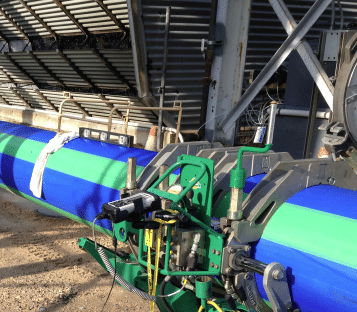

The team completed 11 individual 20-in. butt fusions to seamlessly join the pipe in less than eight hours with two men and one McElroy TracStar 500 fusion machine. The self-propelled, tracked machine features a strong hydraulic facer for fast and efficient facing of the pipe ends. To increase accountability on the job, the team used a McElroy DataLogger to record all of the times, temperatures, and pressures of every fusion weld.

“Although this was the first project I personally used aquatherm on, I previously had seen it in training seminars and it had been recommended by [our local distributor],” Chris Stalnaker, Superintendent of W.W. Gay Mechanical Contractor, said. Stalnaker was comfortable installing the aquatherm pipe because “it was a very simple process” and “easy to handle and maneuver around.”

The mechanical contractor team also helped the fusion process proceed quickly and smoothly by using a McElroy PolyHorse pipe-handling system, which enabled the contractor to load up to six 19-ft pipe sections and have them ready to be loaded into the machine and fused.

The installation process was quick: It was completed within 24 hours, meaning the building experienced very little downtime.

Additionally, the PP-R pipe was buried without insulation because it has a thermal conductivity k-factor of 0.15W/mK.

Carbon-steel pipe must be insulated not only because of its lack of thermal efficiency, but also because it will corrode from the outside and deteriorate badly over time. Polypropylene pipe can be buried directly in the soil with no concerns about deterioration and will experience only nominal heat gain.

Direct burial of the pipe without insulation represented a big labor and time savings for the contractor and a major cost savings for the university.

PIPING FOR AN ECO-FRIENDLY FUTURE

Additionally, direct-buried PP-R pipe will not leach into ground water and has no negative environmental impact. Polypropylene also requires less energy for initial production than other piping materials and involves none of the environmental effects associated with mining operations. That’s important for an environmentally conscious institution such as UF.

aquatherm pipe’s life expectancy of 60+ years is more than three times the life expectancy of carbon steel. Fully recyclable and long lasting, the pipe will never scale, pit, corrode, or rust as steel will, and because it is hydrophobic, it will not suffer from microbial-induced corrosion such as cryptosporidium.

Pleased with the results, the mechanical contractor team already has installed a 24-in. supply and return in the same facility. Stalnaker said he would definitely use aquatherm pipe again in the future.