WHEN QUALITY MATTERS – MAIN STREET BREWERY SELECTS AQUATHERM PIPE FOR ITS BREW HOUSE

MSB owners selected aquatherm pipe for their systems and it ended up providing labor savings of at least 30%.

The Challenge

Main Street Brewery needed a piping system that could reliably transport the precious, filtered water and expensive glycol without leaks while also allowing for easy expansion.

The Solution

MSB owners selected aquatherm pipe for their systems and it ended up providing labor savings of at least 30%.

A PIECE OF HISTORY TURNED INTO A SOCIAL HUB

If you take a walk down the historic Brewery Creek in Vancouver, BC, you’ll find a unique artistic community with a rustic building that formerly housed Doering & Marstrand Brewing Co. and then the Vancouver Brewery in the early 1900s. The now rustic building was even used as an auto garage. The current inhabitants you ask? Main Street Brewery (MSB).

The MSB owners wanted to preserve the vintage feel of the historic building and turn it into a social hub once more. Main Street Brewery completed refurbishing its historic building in May 2014. Located in Vancouver’s Brewing District, MSB will serve its popular Pilsner, three year-round beers, and a monthly special on cask and draft.

In 2010, Main Street Brewery was founded without an official address because owners couldn’t find just the right location. They had Russell Brewing produce their brews in the meantime.

Now they have a place to call home, and brewer Jack Bensley and owner Nigel Pike have the experience to make it shine. Bensley is the former head brewer for Russell Brewing Co. and Pike owns and operates local restaurants.

GOING WITH THE CUTTING-EDGE, YET ESTABLISHED

When Bensley used copper piping for glycol and water at another brewery, he experienced a costly glycol spill due to a small crack in a fitting. He knew he didn’t want to deal with that again. Bensley said, “We didn’t want to cheap out.”

So when Pike found aquatherm, Bensley was interested. They learned that aquatherm is a 40-year-old German company that creates highly engineered polypropylene-random (PP-R) pipe systems which have proven reliable in various applications worldwide. From potable water to heating distribution to chemical transport, radiant, compressed air and more, aquatherm pipes are becoming increasingly popular and for good cause: aquatherm pipes are saving building owners and contractors precious time and money with fast heat-fusion connections and virtually maintenance-free pipe systems.

Pike and Bensley reached out to local sales representative, Peter Way with Hy-Line Sales based out of Langley, BC. Way connected the Main Street team with the local EMCO representatives who serve as the local aquatherm distributor. EMCO is a nationwide plumbing distribution company that aligns itself with the top brand names in the plumbing industry to ensure quality and consistency to its customers. Way and local EMCO rep, Jeff Pickell, answered all of Bensley and Pike’s questions.

“We went and checked out the product at EMCO and as far as ease of install, rated for what we need it for, and the inherent R-value on the cold water, I didn’t think it could be beat,” Bensley said. “It was cheaper than copper and instead of two months to install, it was done in two weeks. We wanted to avoid condensation from copper as much as possible.”

FOR WATER’S SAKE

When asked why aquatherm was selected for the domestic water supply, Bensley responded, “I was concerned for the water. We already have great water here and then we have a great filtration system. I don’t want the water to be ruined after having spent so much money. That water becomes the brewing water I mash in.”

Pike and Bensley turned to Barry Murray, experienced local plumbing contractor and owner of Neighbourhood Plumbing, for help installing the aquatherm pipe. Neighbourhood Plumbing has been in business since 1994 and performs domestic and mechanical process piping work in the light commercial, retail, and food industries. MSB owners introduced aquatherm to Murray.

“I was pretty excited,” Murray said. “I liked the idea and as soon as I saw the cutaways and the qualities and benefits of the [aquatherm] pipe, I was stoked about it. I had piped a brewery before and I knew the type of problems that are common in that kind of industry with copper and PVC being used. PVC was a constant battle. The mere fact that there are no glued joints is a big deal. I like how aquatherm is more professional and cleaner looking.”

Pickell and Way provided Murray and the Main Street team with proper aquatherm training within a half day and delivered all the pipe they needed to their doorstep.

The project officially began in August 2013 but there were quite a few periods of inactivity because they had to work out various legalities. Murray and his MSB helpers installed a total of approximately 400 ft of aquatherm green® and aquatherm blue® ranging in size from ½-in. to 1½-in.

Bensley explained the aquatherm piping installations, “Range from cold water to brew house, some hot water piping, glycol supply and return, and reclamation of warm water from heat exchangers which we return to the hot liquor (brewing water) tank for reuse.”

MAKING A BREW THAT’S ‘WORT’ THE WAIT

aquatherm pipe is involved throughout the brewery process. First, all the supply water is filtered through an activatedcarbon water filter and then transported through 1 ½-in. aquatherm green. Directly after the malt is taken through the mill and converted into grist, it’s transferred into the mash tun and hydrated with water supplied by ½-in. (cold) and 1 ½-in. (hot) aquatherm pipe, so mashing can take place.

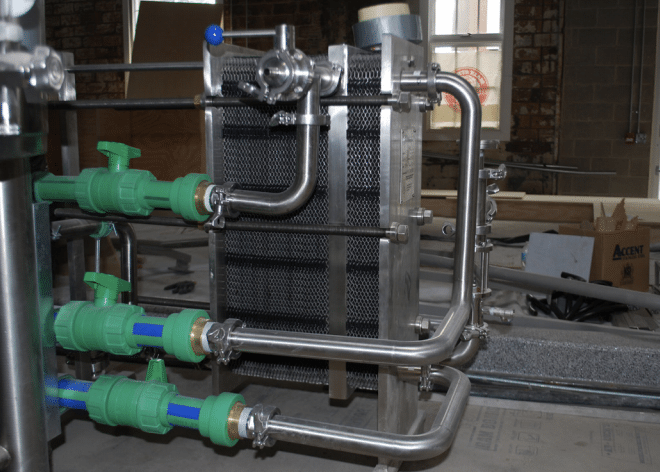

After the resulting mash is complete, the liquid (wort) is strained from the grains, and transferred to the brew kettle. Wort is boiled in the steam-fired brew kettle, where more ¾-in. aquatherm pipe connects to the condensate stack, the boiler feed tank, and the automatic boiler blowdown tank (which is connected via ½-in. aquatherm). The 1 ½-in. aquatherm Blue and Green pipe transports the glycol and cold water to the twostage heat exchanger to cool the wort once the boil is over.

Within the glycol application, 1 ½-in. aquatherm headers and ¾-in. drops are tied in to supply the fermenters and conditioning tanks. Additionally, the glycol-cooled fan unit in the keg fridge is connected with ¾-in. aquatherm.

LEAK-FREE – THE WAY TO BE

After the installation was complete, the inspection took place. “We had the plumbing inspector come in and had it up to 200 psi and not a drop!” said Bensley.

“Never had one leak when we tested it,” Murray added. “I can’t imagine a system of that size in any other pipe material not having a leak. There’s always a pinhole or a joint leaking somewhere.” Not only did aquatherm hold up without leaks but it also provided great cost savings.

“As far as labor goes compared to copper, forget about it,” Murray said. “Huge savings in labor compared to copper. We weren’t working with any mechanical drawings and we had to design it all on the spot and work around a lot of machinery. I would say despite all those little hurdles, being first-time users and the designing and working around very expensive equipment, doing things very slowly and carefully, it was at least 30% faster than copper—minimum. Definitely a much speedier installation.”

Labor savings is a nice feature if the product lasts. And fortunately aquatherm pipes are built to last and the company stands behind its piping systems by offering a 10-year multimillion dollar warranty as long as the pipe is installed by aquatherm-trained professionals. Although Bensley said the warranty didn’t play a role, he said, “It was a bonus.”

The completed brewery including the tasting lounge, brewery, and basement is approximately 10,000 sq ft with four fermenters; there is still plenty of room for expansion. The brewery officially opened in May 2014.

ANTICIPATED EXPANSION ON THE HORIZON

“aquatherm was also chosen so we could add fusions and more tanks,” said Bensley. “We allowed for more piping to go up there in the future. As far as actual fusing I was amazed at how quickly and easily it went. We just kind of blasted through it. The bulk of the actual work was probably a week and a half with a couple days at the beginning laying it out, and then tying it all together at the end. There is some custom stuff we did. We are tying into a heat exchanger at the end of the glycol run and converting to stainless steel tri-clamp fittings.”

While Bensley chose aquatherm for easy expansion of the historic brewery, Murray is also looking for other big projects to utilize aquatherm again.

What started in a shared brewing space is now set in a unique, revitalized vintage brewery with long-lasting piping to keep the brewery pumping out delicious brews for many years to come and easy expansion whenever it’s needed.